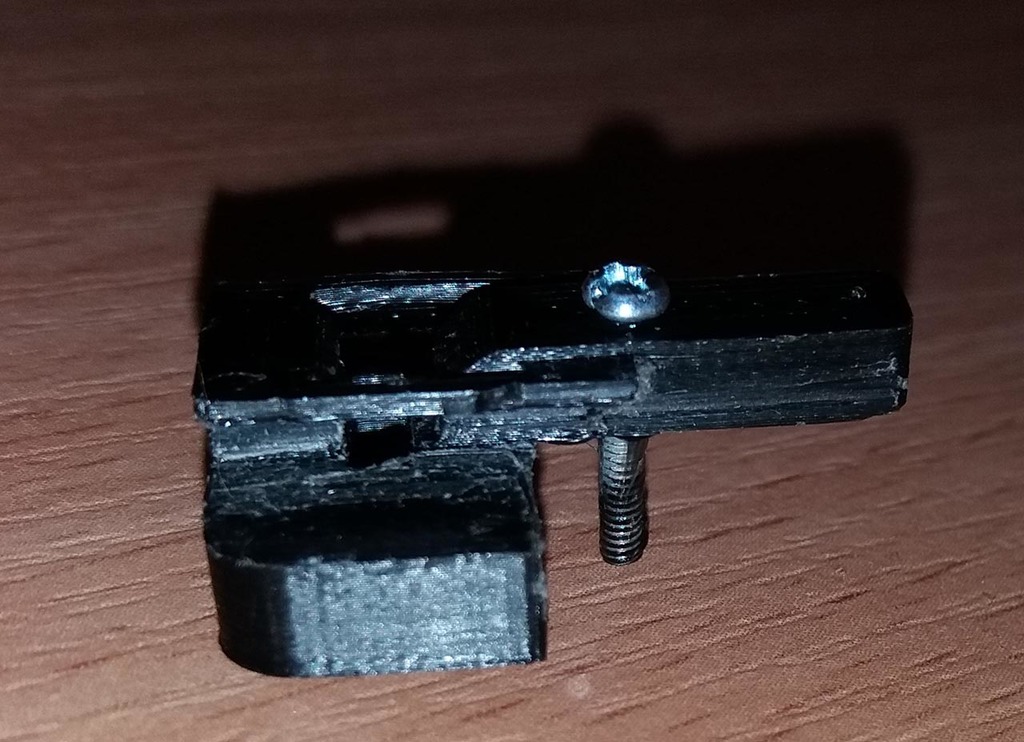

Hook for mini gantry for 20x20 aluminum extrusion x-axis conversion

thingiverse

There's a great x-axis conversion for 20x20 aluminum extrusion. https://www.thingiverse.com/thing:1285301 I did a remix for it to work on my Tronxy P802MA printer. https://www.thingiverse.com/thing:2766399 However, the conversion requires using a 20-tooth pulley and idler, otherwise the belt is not parallel to the axis. To understand, with a 16-tooth pulley/idler, the problem isn't visible in the center of the bed because the error is only 0.006mm. But close to the edge, the error becomes as large as 0.5mm. I didn't want to use a 20-tooth pulley/idler because resolution drops by 25% and torque also decreases by 25-28%. So, I created a special hook that pushes the belt into the extrusion, making the belt go parallel to the axis. I'm testing it now, and my first test prints turned out great - not worse than in the center of the bed. The whole x-axis conversion just makes everything better. I provided two versions: one with a very thin flange (only 2.4mm) that can break off easily; the other has two 1mm holes where you can put little metal pieces to secure it. Installation is tricky - you'll need a longer piece of belt or tie a thread to one end to pull it through the holding hole later. The procedure: 1) Secure one end of a belt into one hook, 2) Insert hook into mini gantry, 3) Trace the belt into the extrusion, through the left z holder, motor holder, turn around, through the right z holder, through the idler, again right z holder (return path), 4) Pull into the right hook belt hole, 5) Insert hook into the gantry, 6) Put the gantry on the extrusion, 7) Secure the belt on the right hook, 8) Tension the belt. Securing the belt is simple - fold the end of belt and push it back into the hole, insert a pin into the belt loop, as small as 0.5mm in diameter. Printing: PLA, turn it 180 around, supports needed, 0.2mm per layer, 100% infill. Lots of work to remove the supports and sand everything so it goes smoothly into the extrusion. I provided SolidWorks files - feel free to play with the design. Originally, I did a hook like this for Y-axis conversion (not published and not finished yet); there it seems as the only way to go. However, for X-axis now, I think it's not really necessary. A better way would be to use 20-teeth pulley/idler and just secure the belt from the inner side, making it as parallel as possible. The error will be negligible this way. Resolution drops from 0.01mm to 0.0125mm, but that's beyond the error introduced even by the extrusion process itself. However, torque decreases by as much as 30%, but we're on wheels now, and don't need as much torque - maybe only for stopping after acceleration, but nobody notices any problems. However, for Y-axis, I think 16 teeth are necessary because the weight is a lot more and we need as much torque as we can get. UPDATE 06/02/2018: Printed 0.5kg of plastic with it - no problem.

With this file you will be able to print Hook for mini gantry for 20x20 aluminum extrusion x-axis conversion with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Hook for mini gantry for 20x20 aluminum extrusion x-axis conversion.