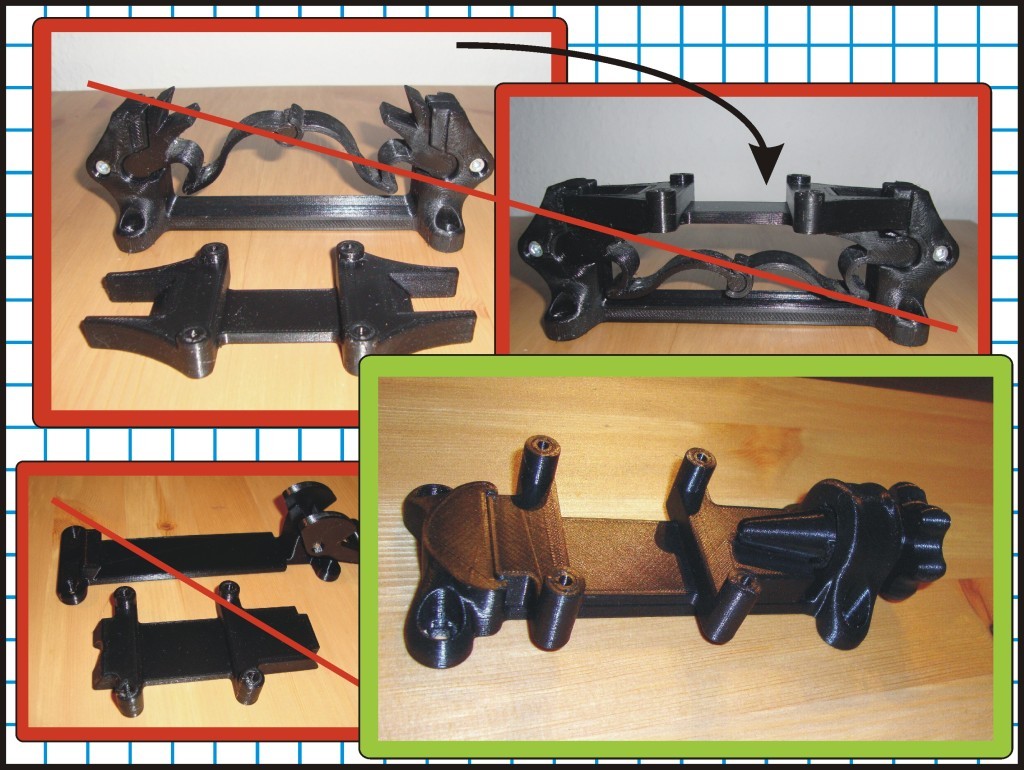

holding mechanism

thingiverse

pps: final design V3 with a seating on one and a screw on the other side. Only 3 parts and can handle some torque. ps: changed the design to a seating on one and an accentric (spiral) mechanism on the other side. Much lower hight, more stability, less parts (4 instead of 5). The first thought isn't always the best. I needed a contraption that could hold down an object sturdily in one plane but also let it be released easily if you take it out of the plane. A mechanism that fits the bill is this bistable spring-operated flip-flop snapping mechanism I don't really know the name of. I thought I share some details I found out about it. The main dimensions in the design process are a and b. a is the distance between the rotational axes, b is the perpendicular distance to the spring joint. For a given pair of a and b you get distance c, the distance the spring has to give from one stable end point to the other. I tried to come up with a single part compliant spring without a joint and failed. The reason is that the spring can only be printed in one position. In the other stable position the internal stresses are high enough that it snaps back to the printed position. The nice thing about these kind of planar mechanisms is that only a slice of it with a width of let's say 2 mm needs to be printed and laid out on a table to see how it's working. I uploaded the parts in stp format for editing.

With this file you will be able to print holding mechanism with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on holding mechanism.