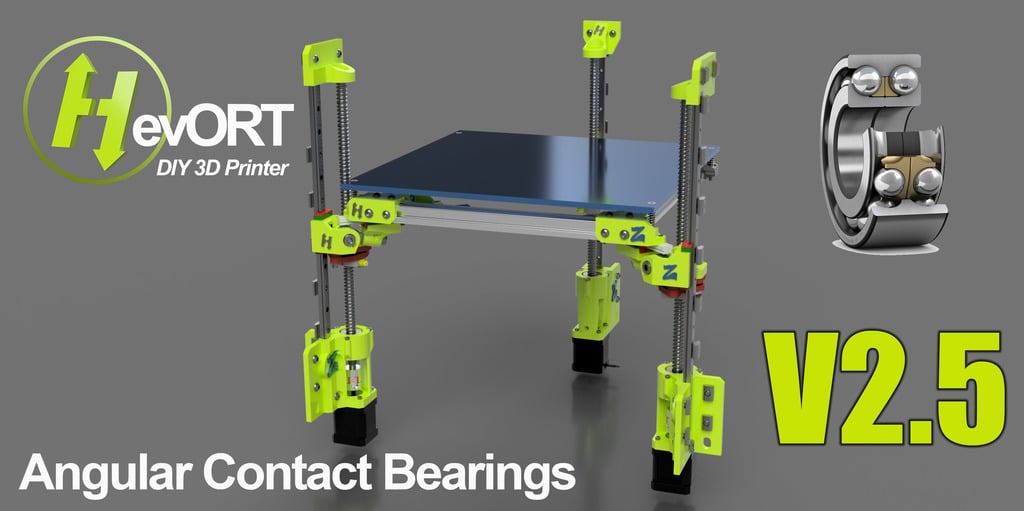

HevORT ZR V2.5 - MGN Rail assisted self leveling Z Axis with Ball screw and Z Wobble Management

thingiverse

<a href="https://forums.hevort.com/index.php"><img src="https://github.com/MirageC79/HevORT/blob/master/images/HevORT%20Logo.png?raw=true" align="left" height="48" width="48" ></a> ##** Join the Support Discussion Forum now to get latest news and more insights on the HevORT.** <a href="https://www.facebook.com/HevORT"><img src="https://github.com/MirageC79/HevORT/blob/master/images/FB_HLogo.png?raw=true" align="left" height="48" width="48" ></a> ##** Join the Discussion Group on Facebook now and exchange about the HevORT.** [](https://miragec79.github.io/HevORT/) _Click the banner to access [HevORT.com](www.hevort.com)_ ##Why is V2.5 better than V2? V2.5 has the same advantages as V2 but also integrates two good things: - First: A double row angular contact bearing is now offering better axial load support to the ball screw. - Second: A quality shaft collar from Ruland is providing a better resting shoulder to the thrust bearing than the poor half lip of a thread the SFU1204 usually offers. ##Why was V2 better than V1? If you managed to source good straight ball screws, V1 is good enough. If you don't want to spend 1000$ only on Ball Screw, then this config might interest you. This configuration will deal with imperfect Ball Screw. Low quality units can be affected by deflection. Since Ball Screw are very rigid, the printed parts will not be able to contain the deviation to the screw, it will be transmitted to the build plate. This deviation will create an Oscillation in the X and Y axis. As the part build in height you will notice an horizontal pattern on your part. With the help of 3 ball bearings sandwiched between 2 plates, these Wobble Wings will transmit only vertical motion while leaving the Ball Screw wobble as much as it wants with no effect on your print. Why not go back to lead screw? This project was developed with non planar printing provisions. This type of printing will require much more travel moves on each Z slider. Ball screws have a much lower friction and wear index then lead screws, this is making them the perfect candidates for this application. Additionally, the weight of this printer build plate is considerable. Especially if scaling higher than 500x500mm XY. Lead screws will be prone to bending under the weight of such bed assembly. Not to mention premature T8-Nut premature wear. Back to Main Page

With this file you will be able to print HevORT ZR V2.5 - MGN Rail assisted self leveling Z Axis with Ball screw and Z Wobble Management with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HevORT ZR V2.5 - MGN Rail assisted self leveling Z Axis with Ball screw and Z Wobble Management.