Heat Sealer For Small Plastic Bags (eg Anti Static)

thingiverse

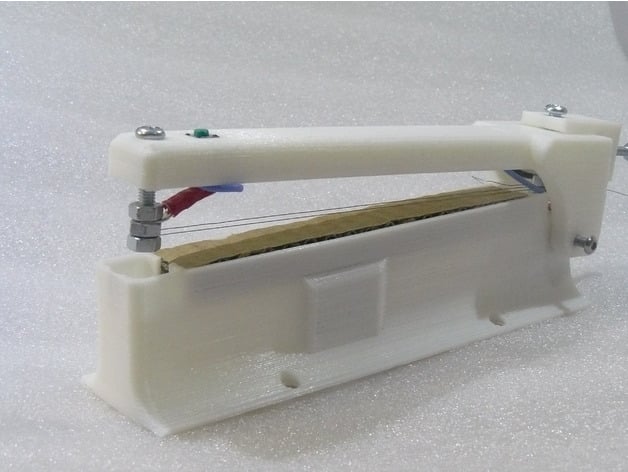

A heat sealer, crafted from durable PLA plastic, indeed functions as intended without succumbing to excessive heat - its robust design withstands high temperatures. Three printable components comprise this innovative device: the arm, base, and tensioner. To complete the assembly, you'll need to incorporate additional materials. Some 0.2mm Kanthal wire will suffice for the heating element; however, other options like Nichrome or Constantan may be used, though they would necessitate different power requirements and sealing times. The specified wire length yields approximately 3.4 Ohms of total resistance when strung as illustrated in the accompanying images. A DC panel socket with a 5.5/2.1mm connector is also required, along with a compact relay coil (15.5mm diameter) such as an Omron G5LA-1. A tactile switch rated for 6mm will serve as the user interface. To prevent inductive spikes from damaging the relay, a diode should be installed; any standard model will suffice. For power supply purposes, either a 10W or higher unit with an output exceeding 5v is necessary, along with a miniature DC-DC converter set to produce approximately 5-6v. Alternatively, a 5v 2A power supply can be used without the need for conversion. In practice, I employed a 12v 10W power supply and a buck converter due to availability. Flexible wire with insulation resistant to high temperatures is recommended for connections; ideally, silicone-coated wire would be utilized to prevent melting of the insulation when in close proximity to the heating element. M3 and M4 screws along with nuts are required for assembly; ensure that M4 nuts measure at least 25mm and M3 nuts at least 30mm. Two ring-style crimp connectors rated for 4mm should be used, as well as corrugated cardboard approximately 2.5mm in thickness (typically sourced from old packing boxes). Hot glue will serve to secure the power socket and switch in place due to spatial constraints. For improved performance, applying Kapton tape along the length of the heating wire can help prevent bag adhesion; this allows for a more effective sealing action rather than causing damage. Simply heat the wire, release the button while holding it closed until cooled, then lift the sealed item. Operating the device is straightforward: connect your power supply (assuming 0.2mm Kanthal wire), position the bag, gently press down on the arm, and hold the button for approximately 5-7 seconds to seal. The exact timing may vary based on factors such as bag thickness; simply adjust the pressure accordingly as the wire heats up. Upon releasing the button, maintain gentle pressure for a couple of seconds before lifting the sealed item. If the bag sticks to the heating element, press the button briefly and it should come loose without causing damage to the wire.

With this file you will be able to print Heat Sealer For Small Plastic Bags (eg Anti Static) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Heat Sealer For Small Plastic Bags (eg Anti Static).