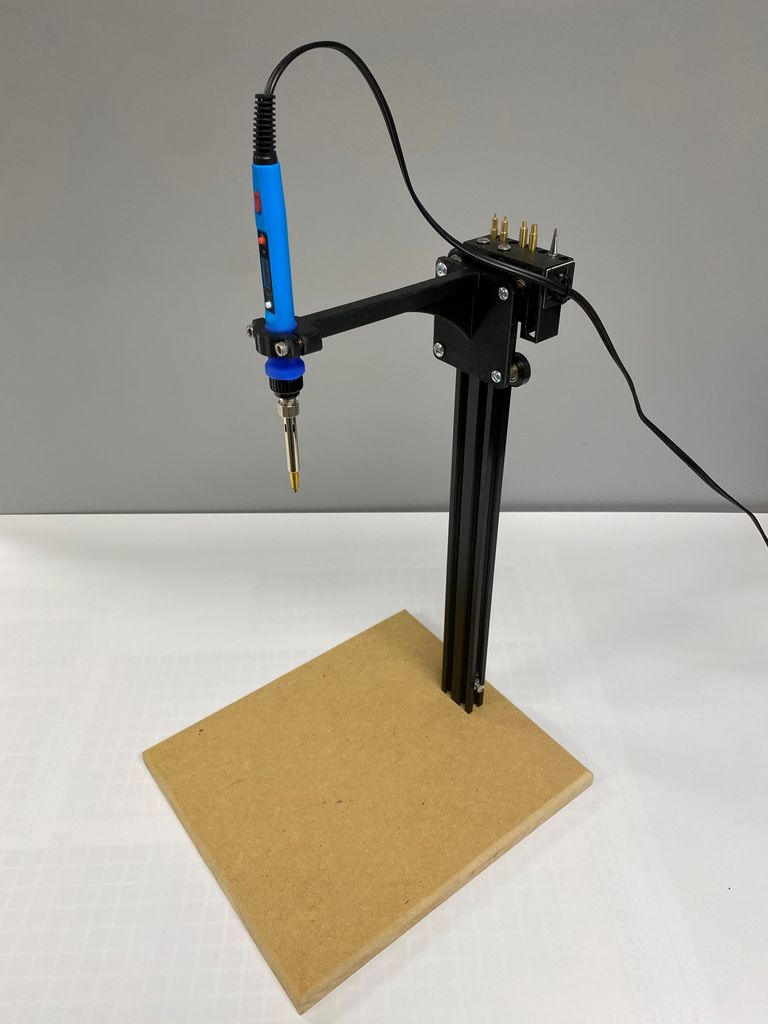

Heat Insert Press

thingiverse

###Gravity press for setting heat-set inserts in plastic parts. Fusion 360 model is here for reference: https://a360.co/3s0OgyT ## Notes - You may need to adjust the brake plate spring retainers to accommodate your spring size. I found that putting a slightly heavier spring at the bottom of the brake assembly helped keep the arm in position best. Also, the spring retainers are not centered. This is intentional so make sure the spring aligns with the center of the wheel. If it does not, simply rotate the plate 180deg. - The arm assembly may need adjusting to fit up to your Iron diameter. - I also added an extra channel nut and screw at the bottom of the rail as a wheel stop to prevent the iron from slamming into the base plate. (shown in pictures but nut listed in parts list) ##Non printed parts list: (1) Variable temperature soldering iron (1) 3/4" x 12" x 12" MDF (1) 2040 450mm Aluminum Extrusion (4) 24mm Plastic Pulley Wheel with Bearing Idler Pulley Gear (2) 5mm bore, 8mm high, Hexagonal Eccentric Column (2) Springs (2) M5-0.8 Heat-set Insert Nuts (6) M5-0.8 x 30mm Pam Head Machine Screws (2) M5 Flat Washers (4) M5-0.8 Lock Nuts (2) #10 x 1/2" Pan Head Sheet Metal Screws (2) #10 x 2" Flat Head Sheet Metal Screws (2) M5-0.8 Channel Insertion Nuts (2) M5-0.8 x 6mm Pam Head Machine Screws *M5-0.8 hardware could be swapped for 10-32 or 10-24 hardware if preferred.

With this file you will be able to print Heat Insert Press with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Heat Insert Press.