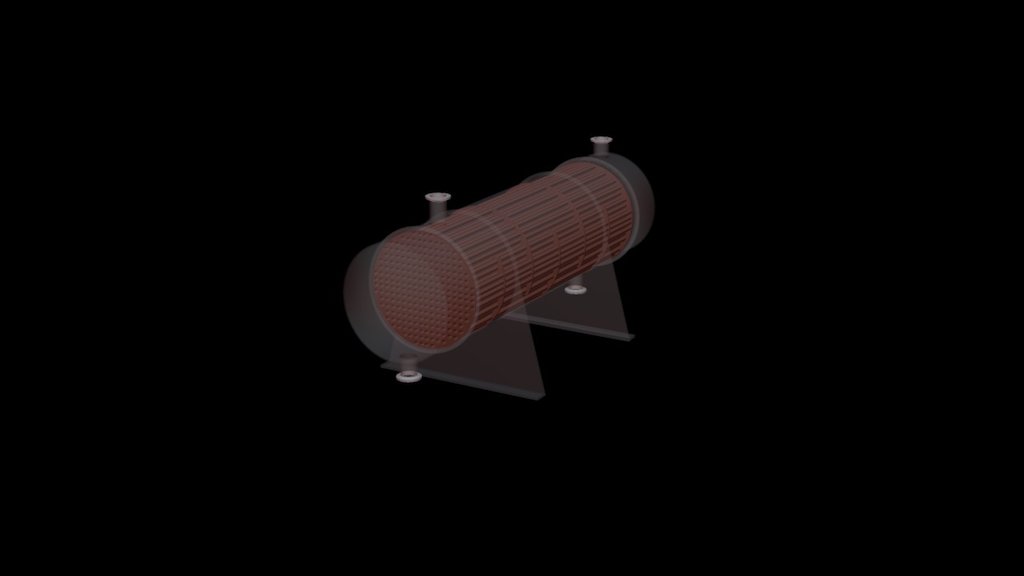

Heat Exchanger Design

sketchfab

Designing a shell and tube type heat exchanger requires careful consideration of several key factors to ensure efficient heat transfer between two fluids that are at different temperatures. This type of heat exchanger consists of a cylindrical shell with a series of tubes inside it, allowing one fluid to flow through the tubes while the other fluid flows around them in the space between the shell and the tubes. The shell side can be divided into several regions including the tube bundle region, where the tubes are located, the baffle section, which is typically placed after the tube bundle to ensure that the fluid flowing on the shell side does not bypass the heat exchanger, and the outlet header. The tube side consists of a single pass or multiple passes through the tubes. The design of the shell and tube type heat exchanger also depends on several key factors including the flow rates, inlet temperatures, and the pressure drop limits for both fluids. Additionally, the material of construction for the heat exchanger is critical to ensure that it can withstand the operating conditions without corroding or deteriorating over time. In order to design a shell and tube type heat exchanger, it is essential to choose the correct number of tubes, the size and spacing of the tubes, and the type of baffles used on the shell side. The selection of these parameters will depend on the specific application and operating conditions of the heat exchanger. A detailed analysis of the design requirements can be performed using computer simulation tools or by consulting with experienced engineers who specialize in heat exchanger design.

With this file you will be able to print Heat Exchanger Design with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Heat Exchanger Design.