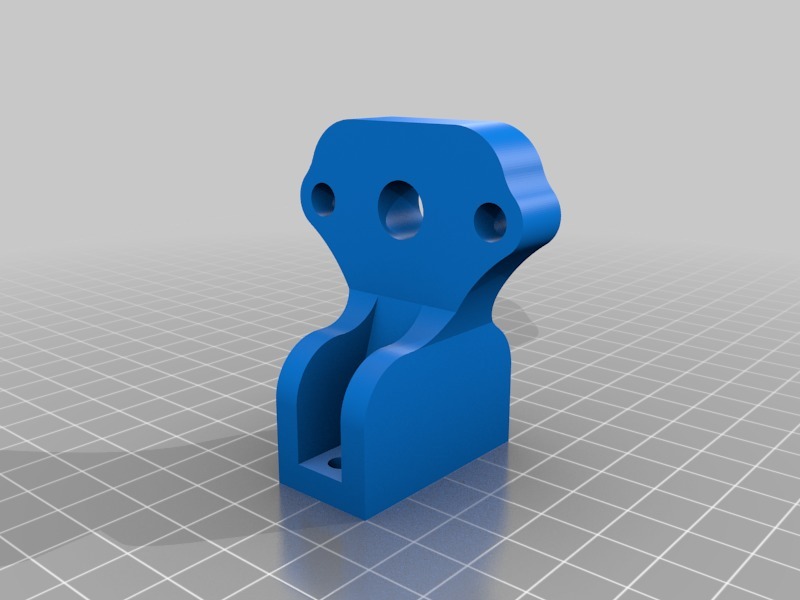

HE3D EI3 Dual Z Drive, Top / Bottom bearing holder - small

thingiverse

The HE3D EI3 printer boasts a dual Z guiding system, but unfortunately, it relies on only one single Z drive located on one side. Furthermore, the clutch is positioned atop the printer, which creates an unacceptable amount of axial force on the clutch - a burden not designed to be shouldered by this critical component. As a result, the clutch deforms, potentially exerting a negative influence on print quality. From a purely engineering standpoint, it would be more advantageous to feature drives at both ends and a bearing capable of withstanding axial forces. In such an arrangement, the lower bearing would effectively absorb these forces. This proposed solution links the screws via a timing belt, driven by a single stepper motor that is designed to maintain perfect sync - typically without any issues. To implement this design, it is essential to machine the ends of the spindles accordingly, thereby facilitating the mounting of gears onto these modified components. The retrofit kit comprises three distinct printed components paired with metal parts (bearing, lead screw, etc.), including: Z-Nut Holder Top/Bottom bearing holder - large Top/Bottom bearing holder - small You will find the remaining two essential items among my uploaded files.

With this file you will be able to print HE3D EI3 Dual Z Drive, Top / Bottom bearing holder - small with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on HE3D EI3 Dual Z Drive, Top / Bottom bearing holder - small.