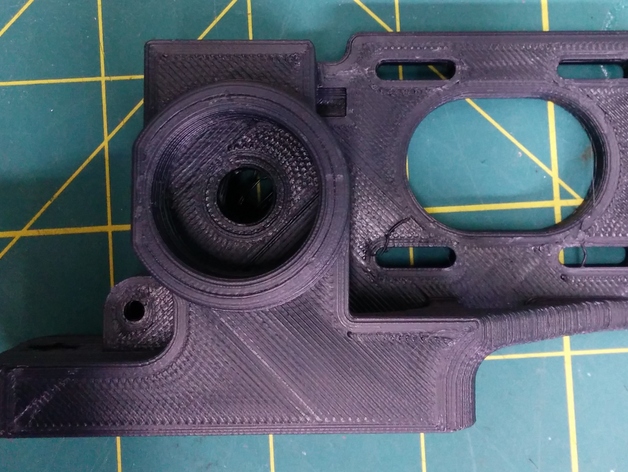

Greg's Wade Accessible Belt Drive Extruder, Rev2

thingiverse

This remix merges Greg's Wade-style extruder with Terawatt Industry's sturdy belt drive design. The combined unit harnesses the benefits of the zero-backlash concept behind Terawatt 00str00der. Note: it is engineered for 3mm filament use. To enhance editability, I've provided Solidworks files for the frame and assembly components. Download any remaining Solidworks files from the original extruder model if you want full access to edit the assembly. Here's an updated design: A heavier-duty main frame helps avoid cracks near the bearings Two 608 bearings are now situated on the non-drive side of the hobbed bolt, increasing stability M4 nut traps have been redesigned for more secure mounting A modified stepper mounting plate improves print performance October 27th, 2015 Update: NITEWING76 graciously allowed me to include idler files within this revised design. September 23rd, 2014 Update: The package has now included a 1.75mm version for added versatility in filament use. This version offers increased clamping force, though you may encounter difficulties fitting it inside the extruder. I've incorporated two configurations within my Solidworks .prt file - the standard 3mm setting and an optional 1.75mm mode. Assembly requires: Components: 65T plastic GT2 pulley w/8mm bore & 5mm flanges (set-screw required) 17T aluminum GT2 pulley w/5mm bore, same flanges (with set-screw too) 88T GT2 belt; fiberglass-reinforced, closed-loop with a pitch of 2mm and dimensions at 6mm width x 196mm in length. Pulleys & belts available at stock drive products, Terawatt industries or Ebay A standard hobbed bolt suffices for your print operation 4 pieces of the essential 608 bearing parts are mandatory Use of the spring assembly guarantees more smooth operation The key components consist of: -2x M4 bolts to ensure firm connection of stepper assembly parts and their subsequent washers & M3 nuts; also four other assorted washers that provide proper mounting for each piece involved with motor mount plate or the hobbed shaft. Be certain to use those correct type for ideal outcomes while you could have no choice other than reversing directions for better control of stepper after installation of this unit. This hybrid design brings greater stability in movement and smoother extrusion flow resulting ultimately in reduced sound output when working on it giving user even quieter experiences during overall printing sessions with every print out done correctly!

With this file you will be able to print Greg's Wade Accessible Belt Drive Extruder, Rev2 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Greg's Wade Accessible Belt Drive Extruder, Rev2.