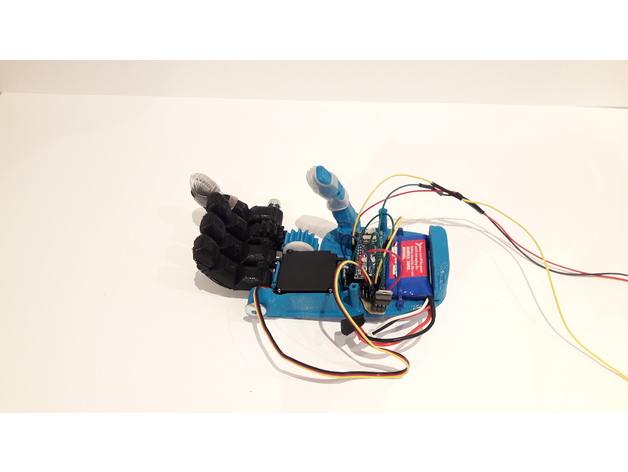

Grasp Low Cost

thingiverse

This project aims to achieve a robust grasp with minimal expenditure on actuators and electronics. You will need to drill through the axis portion of the fingers using an M5 drill bit. It is essential to drill two M1 holes and one M3 hole into the plastic gear in order to secure it with the servo accessory. Additionally, you can cut the plastic axis of the palm and perform the same drilling operation using an M5 drill bit. The only components required for this device are: A standard servo motor, such as the Tower Pro MG995. A voltage regulator set to 6V. An Arduino Nano microcontroller board. A LiPo 2S 7.4V 1000mAh battery pack. A MyoWare muscle sensor or alternative sensor to control it.

With this file you will be able to print Grasp Low Cost with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Grasp Low Cost.