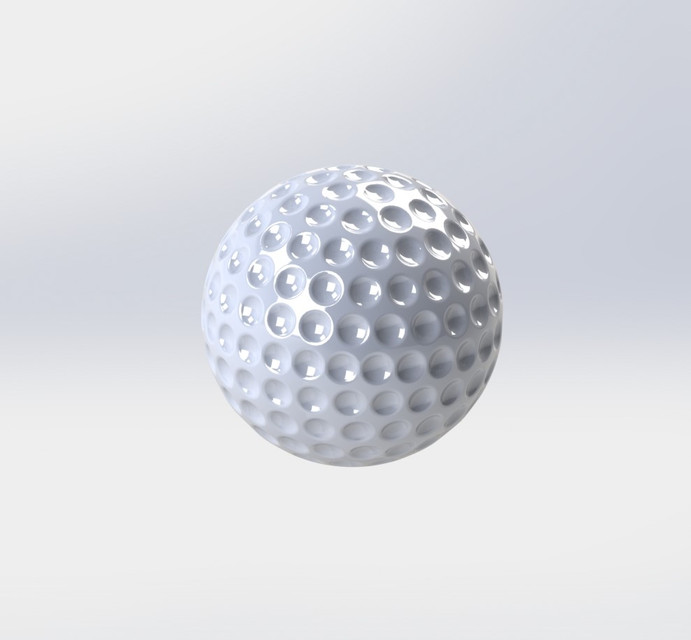

Golf Ball

grabcad

Golf ball designers carefully craft every detail to achieve optimal performance on the course. The dimpled surface of a golf ball is designed using computer-aided design (CAD) software like SolidWorks, taking into account factors such as aerodynamics and spin rate. The golf ball's core is typically made from a rubber compound that provides a high coefficient of restitution, allowing it to bounce back quickly after impact. The outer layer of the golf ball is usually made from a surlyn or urethane material, which provides a durable and resistant surface. This outer layer is designed to withstand the rigors of flight and provide a consistent feel for the golfer. Golf ball manufacturers use SolidWorks to simulate the ball's behavior in various conditions, including wind, rain, and temperature fluctuations. By analyzing these simulations, they can fine-tune their designs to achieve optimal performance in different situations. In addition to designing golf balls for optimal performance, manufacturers also use SolidWorks to create molds for producing the balls. The software allows them to design complex mold geometries that ensure precise replication of the ball's design. The use of SolidWorks in golf ball design has revolutionized the industry, enabling manufacturers to produce high-quality products with unparalleled precision and consistency.

With this file you will be able to print Golf Ball with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Golf Ball.