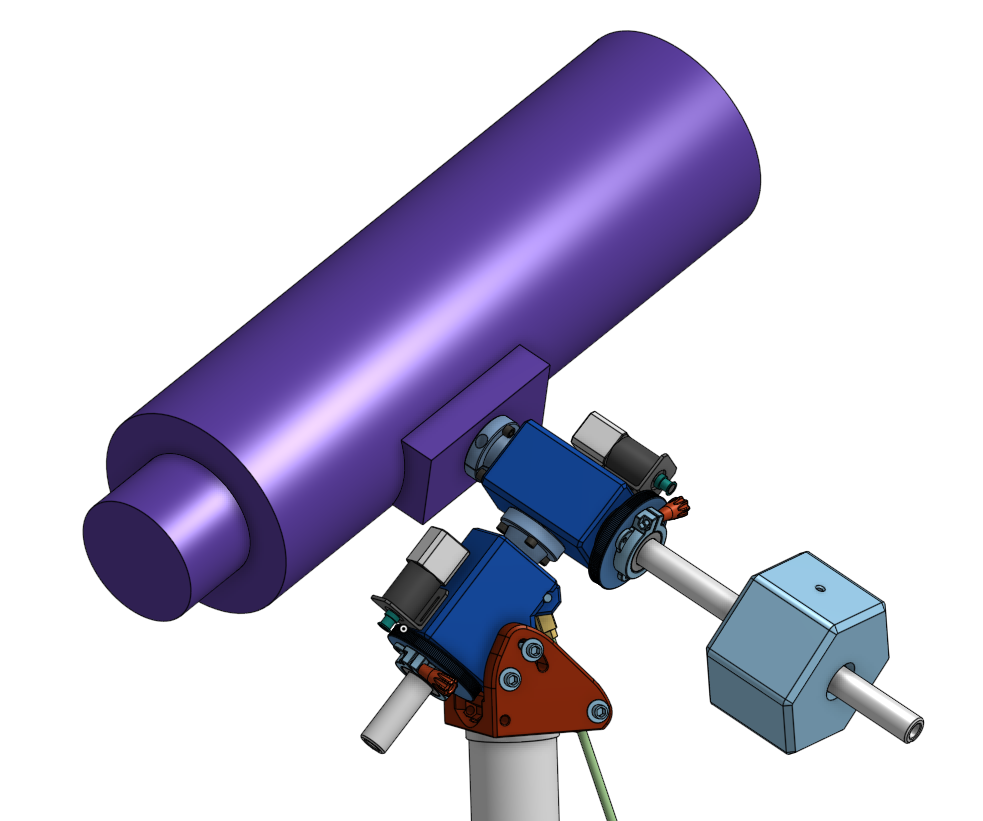

Go-Kart OnStep Telescope Mount

thingiverse

This is a 3D printed GoTo mount using hardware from GoKarts (axels, bearings, hubs). So it is capable to carry up to 40 lb scopes, at least for visual (80lb total with counterweights). https://youtu.be/qlFRljpmP_E The motivation was to design supper affordable GoTo mount for up to 12" scopes, capable for some short-exposure photography. However the total amount of money I've already spent on motors and other hardware parts is around $350. For the same amount of money it is possible to get a used but functional CG5 mount with a tripod. This seem to be better investment than 3D-printed DIY, just because stiffness issues of the plastic parts and timing belts. What renders long-duration DSO exposures impossible. Anyway - it is sometimes hard to get over "because I can!" when asking yourself "Why?" about another stupid idea in your head. So ... - here you have it! ### All the mounting hardware is obtainable with no need in additional machining. The main source - GoKart parts (e.g. http://www.bmikarts.com). It appears they have some neat things for this application, like precision machined aluminum hollow axle (1"-1/4 OD) and compatible hubs. There are various axle options available if you want more stiffness (like chromoly or non-hollow solid steel or solid aluminum). # BOM ## Main hardware parts: * $35 - D 1.25" aluminum hollow axle , 36" long is enough (should be cut into two pieces - 12" for RA and 24" for Dec with counterweights); * $30 for 2x aluminum wheel hubs. to connect RA axle with Dec assembly and Dec axle with saddle. * $35 for 6x R20-2RS bearings (1.25" ID fitting the axle). 3 bearings per axle, 2 per each 3D-printed axle block (durk blue in the image) and 1 goes into timing wheel clutch assembly. * $15 for 4x set-screw collars. 2 per axle, unlike clamping collars these don't have bolts sticking out. So it works well as large diameter smooth friction surface for clutch assembly. ## Go To Electronics: * $30 for OnStep controller * $20 3s LiPo battery ## Saddle * $40 for 2x small SvBony clamps ## Options on motors * $120 for 2x precision geared stepper motors 1:100 (https://www.omc-stepperonline.com/nema-17-stepper-motor-l39mm-gear-raio-1001-high-precision-planetary-gearbox-17hs15-1684s-hg100.html) these have very small backlash. + $30 for 10 mm wide 20T pulleys and GT2 belts (386 mm long). Reduction ratio with 180T axle wheel is 9. So the total reduction ratio with stepper gearbox is 900. With 32x micro-stepping of 200 steps/turn of NEMA17 it results ещ 0.23 arcsec resolution. So this is $150 total to power up both axes. * Another option is using regular steppers with a cheap ($35) worm-wheel kit from AliExpress (see pictures) and 2x...4x GT2 belt-drive for a worm. If you add cost of stepper and belt drive parts (belt with pulleys) it will be around $120 for both axes. With 4x belt-drive and 400 steppers the resulting resolution will be around 0.28 arcsec. Will provide stiffer overall drive without less backlash (then over-axle belt), but requires much more 3D printed parts than in this assembly. I am likely to try this out some time later. ## Misc hardware * 3/8"-24 x 2"-1/2 hex-cap bolts, nuts and washers * 3/8"-24 Heim Joint and 12" threaded rod (for RA tilting mechanism) * M4 x 20 mm bolts and nuts for motor mounting brackets * M5 x 20 mm bolts and nuts for clutch clamp assembly * M6 x 35 mm bolts and nuts for clutch and counterweight knobs * gym plates (2 inch inner diameter) sourced from eBay/craigslist * 3.5x40 mm wood screws for counterweight adapters (2" OD into 1"-1/4 ID) * 3/4" threaded rod for bearing press tool # CAD files: you might wanna adjust dimensions to your printing tolerances https://cad.onshape.com/documents/bca0c1425154819f5e2f4f46/w/cfde02c2256e9d865052a4ce/e/5f61c7a80bd4534595caa60b (just create an OnShape free account and copy documents to yourself) Printing: Axle blocks are recommended to print out of tough material. Like Nylon. In my case it was Overture Easy Nylon using 0.8 mm nozzle, 0.4 mm layer height. 255C. Temp shrinkage scaling 1.0066 (or 100.66%). Knobs were printed on resin printer, they use M6 hex-cap bolts which were glued in with UV resin.

With this file you will be able to print Go-Kart OnStep Telescope Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Go-Kart OnStep Telescope Mount.