Glasses including manufacturing tolerances

thingiverse

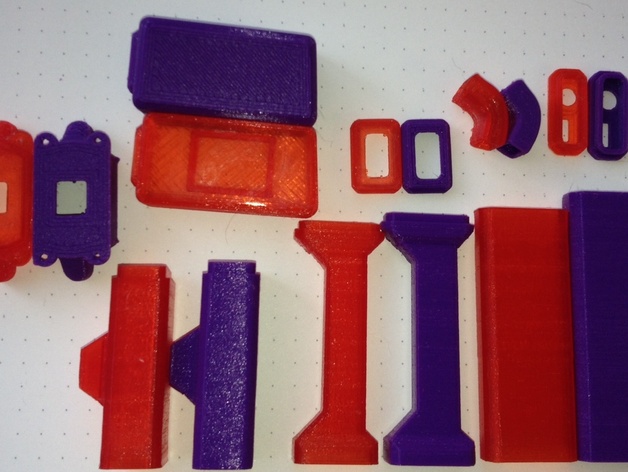

Sadly no manufacturing process is able to create a part with a +/- 0mm tolerance level. Engineers must utilize tolerance analysis when producing mating parts to ensure they fit together properly. This requires careful consideration to prevent costly misfits like the ones encountered here, where assumed zero-tolerance parts caused significant problems in assembly. Fortunately, performing a worst-case scenario analysis helped rectify the issue by allowing for a +/- 0.1mm tolerance range, enabling all parts to interlock smoothly. Using specialized software, I utilized netfabb to resize the parts precisely. As mating parts were connected via straight lines, observing how large each part grew was straightforward. Interestingly, different materials slightly altered the tolerance calculations. Consequently, two versions of the problematic elbow were created to accommodate potential manufacturing variability, showcasing its significance in component assembly and interconnection.

With this file you will be able to print Glasses including manufacturing tolerances with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Glasses including manufacturing tolerances.