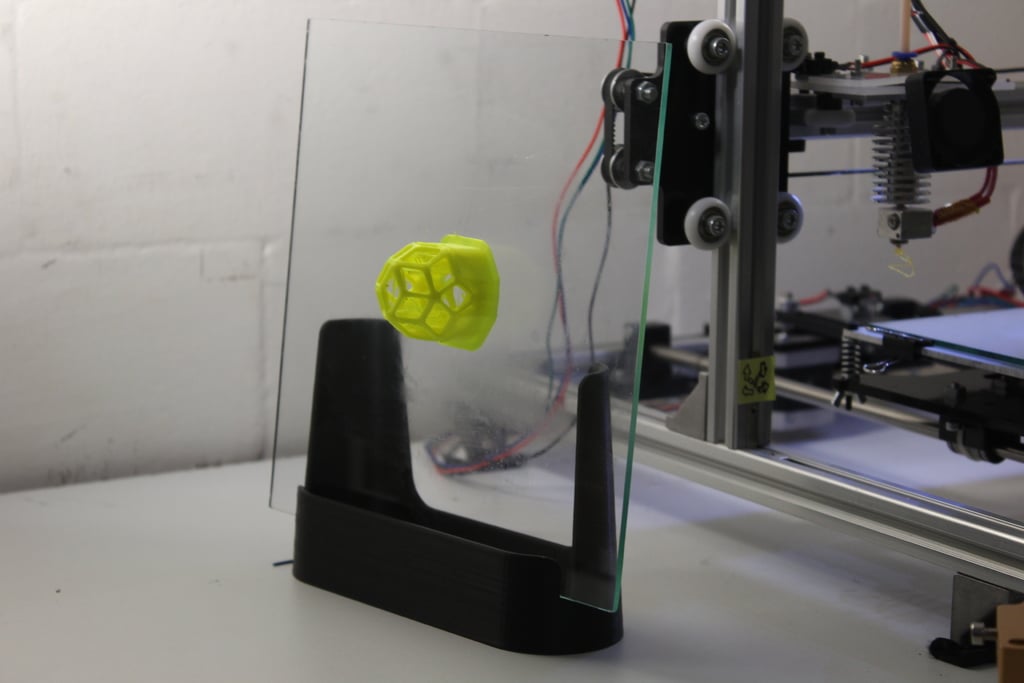

Glass Cooling/Drying Rack

thingiverse

The best advice I've found for bed adhesion is to use a 1:10 solution of white glue (PVA) in water and spread it onto a glass printbed with a brush. Let it dry using the heated bed. However, there were some issues with this approach:\r\n\r\n- This method works extremely well with PLA, making parts so adhered that they can take 10s of kg to separate if the glass is still hot.\r\n- As the glass cools and shrinks, the part pops off the glass on its own. However, if it's still on the printer, this process takes several minutes. The metal core of the printbed stores a lot of heat.\r\n- Normally, you add more PVA solution before each print. After ~15 cycles, dirt and oils accumulate, requiring the glass to be washed. PVA is easily removed with warm water, but the glass needs to dry afterwards. You can use isopropyl alcohol to speed up this part.\r\n- In a commercial printing setting, it's essential not to waste time between prints.\r\n\r\nSo, I designed a simple cooling rack by using two identical glass panes. This allows me to swap them after each print with zero downtime. The open back of the rack enables the glass to cool down quickly, and large prints pop off on their own in just a few minutes.

With this file you will be able to print Glass Cooling/Drying Rack with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Glass Cooling/Drying Rack.