Glass Clip system

thingiverse

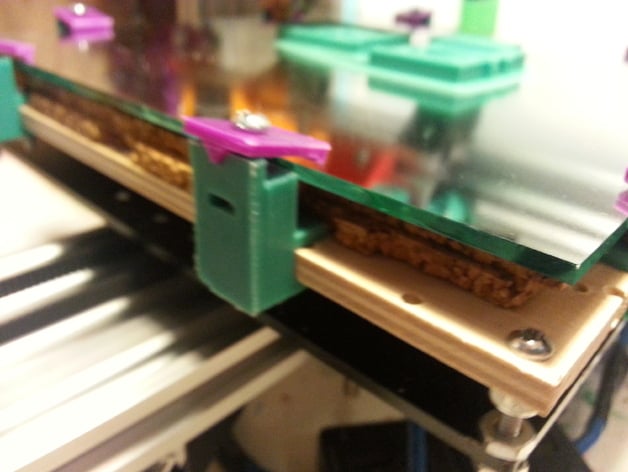

This clamp bolts directly onto a standard 6MM plywood base and provides ample room for two layers of cork insulation underneath the glass and silicone heating bed. The clip's holes are designed with slotted configurations to enable precise angle adjustments while clamping the glass firmly against the bed. Securing the clamp pad to the clip is achieved using 6-32 x 1/2" bolts and a captured nut, while a pair of 6-32 x 3/4" bolts secure the clip itself to the bed with utmost stability. As a result, these custom-built clamps are capable of firmly holding even large pieces of glass in place, measuring up to 220mm on each side. To assemble these precision components, it's essential to follow a clear set of instructions: The initial step involves printing out two clips and four clamp pads using a high-temperature filament such as ABS (which I successfully printed at a bed temperature of 90C and hotend of 245C). The suggested infill percentage for these print jobs is around 30%, along with a carefully optimized layer height of 0.2mm, achieved through consistent printing speeds reaching up to 72 MM/sec

With this file you will be able to print Glass Clip system with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Glass Clip system.