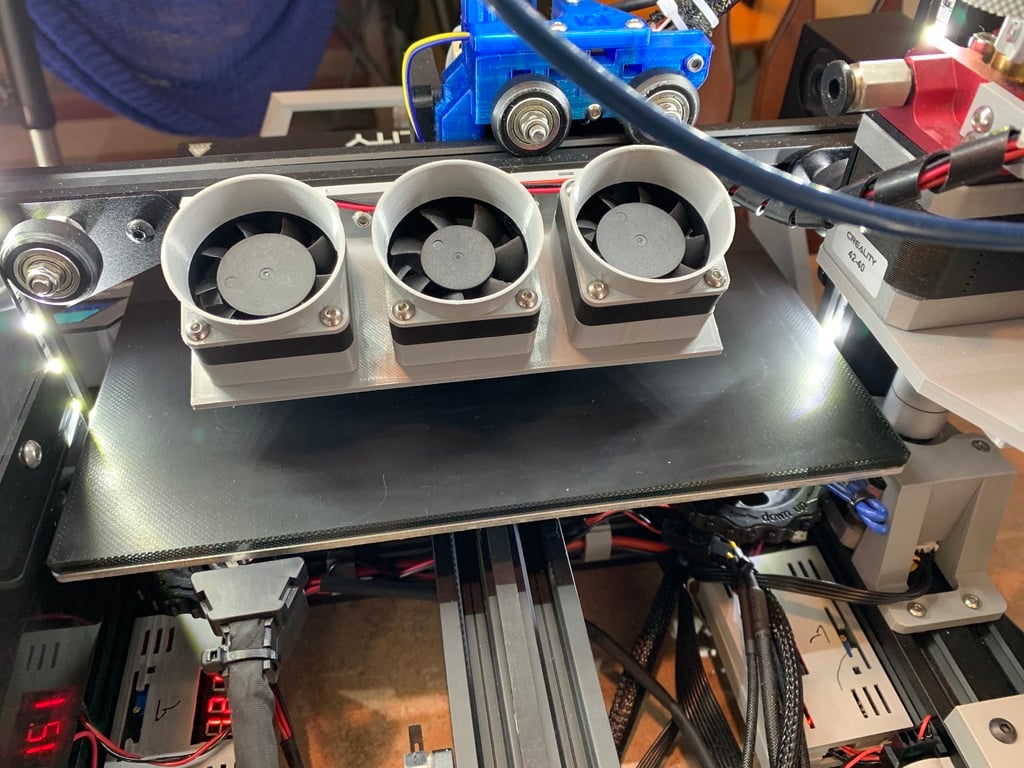

Glass Bed Automatic Cooling System

thingiverse

I installed a Creality glass bed on my Ender 3 Pro and I'm completely satisfied with it. The only "problem" is that it takes too long to cool down before releasing the print, which is frustrating for someone like me who's always in a hurry. So, I decided to come up with a solution by creating a bed cooling system. My design criteria were: 1) Use parts I already had on hand; 2) Keep it compact and out of my way; and 3) See how much I could get out of those cheap little 4010 fans. Here's how it works: when the print is finished, the bed slides forward, trips a limit switch, and turns on three fans to cool down the bed faster. I chose three because that's how many I had available - more is always better! Some people may ask if this really works. Let me tell you, it does. First, let's talk about the fan stack: - Part 1 is a 40mm FanFunnel that I borrowed from clough42. You can find his original design on Thingiverse: https://www.thingiverse.com/thing:343026. I did some testing and discovered that adding this inlet to a cheap 4010 fan quietens it down and improves its efficiency. - Part 2 is the fan itself - I bought a pack from Amazon, but you can find them cheaper on AliExpress. Here's what I used: https://www.amazon.com/gp/product/B07Q5R9HF4/ref=ppx_yo_dt_b_search_asin_title?ie=UTF8&psc=1. - Part 3 is the turbine duct - I designed this myself, but all my ideas came from a great video by Alex Kenis. You should check it out: https://www.youtube.com/watch?v=SX-okOHvh1Q. Adding this outlet duct doubles the output of these little fans! So, does it really work? Here's what happened during my test: with an ambient temperature of 22°C, I heated the bed to 60°C and let it stabilize. Then I let it cool down three times and averaged the times - it took about 38 minutes. With the three fans running, it took around 18 minutes to cool down. Because the fans are mounted on the x-axis, the cooling time changes with part height - 60mm and below takes about 21 minutes to cool, while 60mm and above takes about 16 minutes. The bottom line is that this system cuts my cooling time in half! Installation: - Assemble the three fan stacks and mount them on the bracket using M3x25 bolts and nuts (or brass threaded inserts for a cleaner install). - Mount this assembly to the back of the x-axis rail using two M2x8 bolts with T-nuts. - There are slots in the bracket for wire ties to keep the wiring neat. - Find a Creality limit switch - you can get them on Amazon or AliExpress. Use the limit switch screws that come with it to screw the switch to the bracket I made, then secure it below the Y-axis near the front of the printer using two M3x10 bolts and T-nuts. - Wire everything up according to my simple wiring diagram. Note that you need the normally open contact on the limit switch - if you get it backward, you'll know because the fans will run at the wrong time! There you have it - happy bed cooling!

With this file you will be able to print Glass Bed Automatic Cooling System with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Glass Bed Automatic Cooling System.