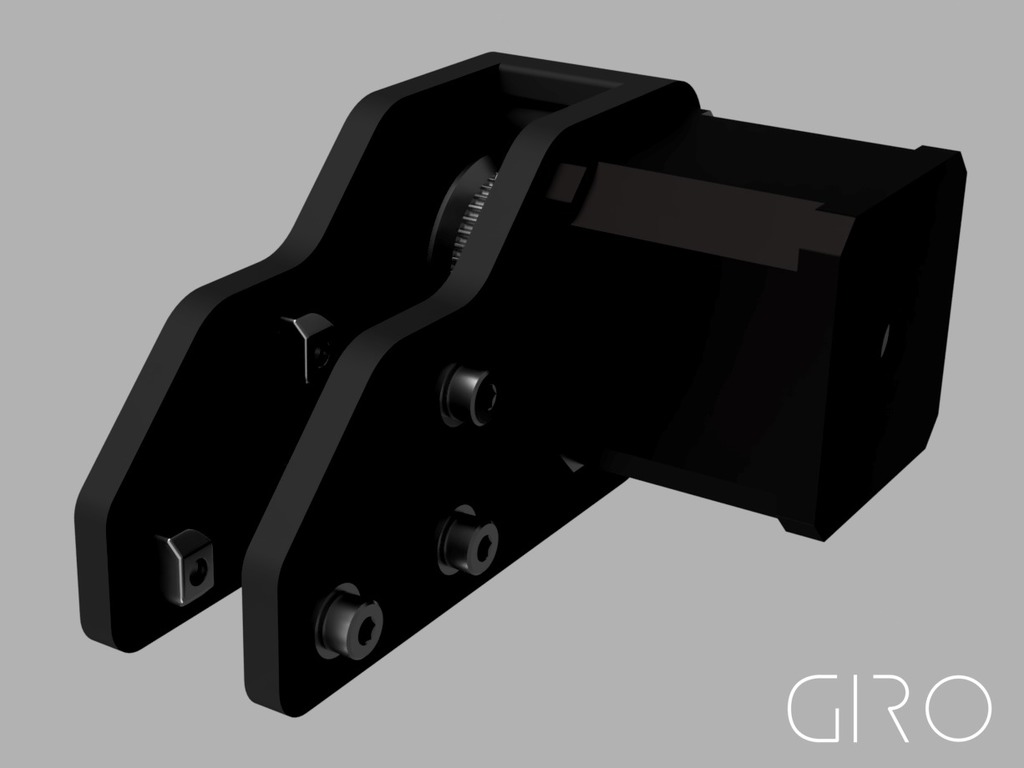

GIRO - TEVO Tarantula / Y-Axis Motor Mount

thingiverse

#### GIRO-TEVO Tarantula / Y-Axis Motor Mount #### #### General #### This Nema17 stepper motor bracket was designed to improve the Y-Axis movement by reducing friction in the idlers due to excessive tensioning, which causes deformed acrylic brackets over time. My overworked Y-Axis bracket uses a 40 teeth (40T) aluminum pulley that should not be printed. I noticed that printing the pulley may cause misalignment of the GT2 belt or the pulley does not stick to the motor shaft and moves across it. The 40T pulley can be purchased on several websites with the following specifications. **40T Pulley** * 40 teeth * 5mm bore * Specifically designed for 6mm wide GT2 belts They look like the one in the picture below.  This design is available in two versions. It depends on which side you mounted the stepper motor on your printer. Just take a closer look at the files, which are declared with the subcontext **right** and **left** to ensure that everyone receives the bracket they need. You will also need to recalibrate your Y-Axis. Read the **Additional Information** section for further details. This design is an addition to my 608 ball bearing Y-Axis idler, called [GIRO-TEVO Tarantula / 608 Ball Bearing Y-Axis Idler][]. You will need additional screws and washers for mounting the idler. The needed parts are mentioned below. **Additional Screws and Washers** 2x M3x35 Screw 2x M3x10 Screw (You may use the original screws of the TEVO Tarantula. They are already mounted on the original acrylic bracket.) 4x M3 Washer 6x M4x10 Screw 6x M4 Washer #### History #### **Version 1.0** This was the first intended design with a 40 teeth (40T) pulley and a first bracket prototype. #### Printing #### I recommend using at least 3 perimeters. Print with a lower speed, for example 30 mm/s, to get more accurate printing. I recommend printing everything with at least 50% Infill. #### Additional Information #### Let me begin by saying that you will need to recalibrate your Y-Axis. You will need to recalibrate the Y-Axis steps. I needed to reduce mine from 80 to 38.8 steps per mm. I suggest starting with a value of 40 and then using a ruler to see if it moves 100mm correctly in the Y-Axis direction. Let me know if there are any problems with the motor mount. I will try to help and correct the designs if necessary. I appreciate any feedback on these mountings. If you like my work and find it really useful, I would be happy if you gave me a small tip as an appreciation for my work. For all of you who have given me a tip.  [GIRO-TEVO Tarantula / 608 Ball Bearing Y-Axis Idler]: https://www.thingiverse.com/thing:3448709

With this file you will be able to print GIRO - TEVO Tarantula / Y-Axis Motor Mount with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on GIRO - TEVO Tarantula / Y-Axis Motor Mount.