Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament)

thingiverse

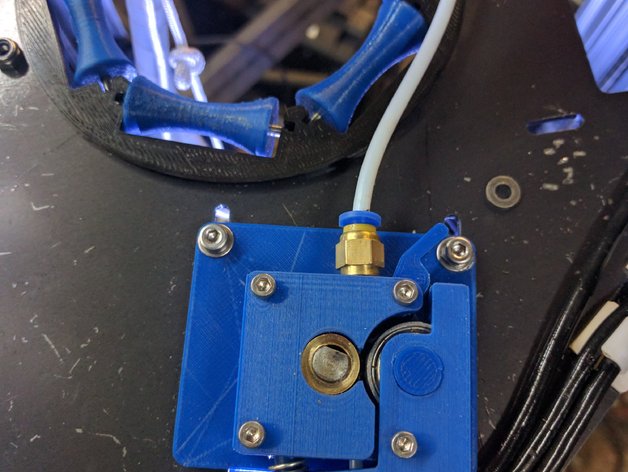

I built and designed my own Delta Printer, seeking something better than what was available within my budget. Initially, I purchased a cheap aluminum feeder that turned out to be less than ideal due to its non-straight filament path and lack of guidance as it passed through the body. Excessive pushing force caused the filament to buckle, resulting in ruined prints. On my original Ultimaker, I printed an iRoberti feeder, which is excellent! However, there didn't seem to be a 1.75 version using push-fit connectors for Bowden tube. Therefore, I decided to start from scratch and create something new. Initially, I used this setup with a regular NEMA17 motor, which worked fine. The parts pictured were printed using it in PolyMax filament. To achieve higher speeds on my printer, I felt that a standard NEMA17 motor just wouldn't provide the necessary torque. Hence, I opted for a NEMA17 with a 5:1 reduction gearbox - roughly five times the torque of a standard motor. In addition to the motor, you'll need: 4 x M3 x 25mm screws 4 x M3 Nyloc nuts (plain nuts will loosen quickly) 1 x 22mm OD, 8mm ID, 7mm thick bearing (608-ZZ type - ZZ means metal shields, which run more freely than 2RS type with rubber shields) 1 x Drive Gear suitable for your motor (*see below) 1 x 4mm, M6 push-fit connector for Bowden tube 1 x 9mm OD 20-25mm long spring (from an eBay spring assortment) 1 x M4 x 16 screw (for tension adjustment) 1 x M4 plain nut (for tension adjustment) Optional: A short length of 3mm OD Bowden tube to guide the filament And, of course, a 3D printer to print the parts! The Drive Gear must be no more than 12.5mm OD. Most Mk7 & Mk8 types are suitable. Motors usually have a 5mm or 6mm shaft - you'll need to measure yours. My geared motor has an 8mm shaft, which is why my 8mm bore gear hasn't arrived yet. Part 'Stepper Mount Temp.STL' is designed for mounting on my printer but should be adaptable to yours if needed. The four inner holes are correct for the geared NEMA17, while the four outer ones fit a standard NEMA17 motor. The filament path is guided throughout, except for about 1mm either side of the drive gear. I've found it works well with PolyFlex and NinjaFlex - probably most other filaments too. To assemble the feeder, heat up an M6 bolt tip (with a lighter) and screw it in first to melt a thread. Alternatively, you can carefully screw it in as it cuts its own thread. The design incorporates a release 'switch' that pushes the bearing away from the filament and holds it released. This is handy for manually loading filament. I used a random spring from an eBay assortment I bought years ago. It should be no more than 9mm OD and greater than 6mm bore - doesn't need to be particularly strong. Mine is stronger than necessary. This design should prove useful! Feel free to share, distribute, or hack it as you see fit! Print Settings: Printer: Simon's Delta Rafts: No Supports: No Resolution: 0.1mm Infill: 40% Notes: I would either print this solid or with a fair bit of infill due to the significant stress on the components.

With this file you will be able to print Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Geared 1.75mm Bowden Feeder for 3D Printer (suitable for Flexible filament).