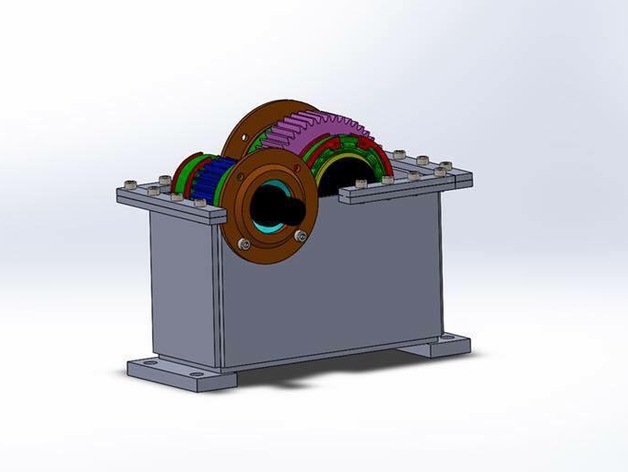

Gearbox

thingiverse

This is a complete transmission assembly, fully operational with interlocking gears.\nTotal dimensions are 270 x 210mm, making it a compact transmission system.\nIt's a prototype transmission model created using SolidWorks 2016 software.\nPrint Settings\nPrinter: \n Cubic Pro\n \n Rafts: \n Yes\n \n Supports: \n Yes\n \n Resolution: \n 0.1mm\n \n Notes: \n A minimum print bed size of 200x200mm is required.\nHow I Designed This Transmission System\nStep 1\n First, create the base part of the transmission system, and you will obtain necessary lengths for your project, then calculate the rest.\n \n Base Part.\n Step 2\n Next, design the two axles and integrate them into the base part.\nRemember to include measurements with tolerances to ensure a snug fit.\n \n Axle 1\n \n Axle 2\n Step 3\n The two axles feature gears, bearings, notes, and lock rings.\nThe gears and bearings are standard parts that can be found in most toolboxes.\n Step 4\n With the top part of the transmission system, you should be able to determine all necessary lengths by yourself, given the other parts' dimensions. This is a project-based exercise, after all.\n \n Top Part.\n Step 5\n Integrate the top part into the base part, and the transmission system is almost complete, except for closing it with two caps.\nYou simply assemble the parts once they're printed.\n \n Cap\n\n \n Custom Section\nTransmission Project.\n Objectives: Students should learn how to create a basic transmission system in SolidWorks, utilizing standard toolbox parts, and that you don't need all information to design a transmission. They will explore various features of SolidWorks.\nAudiences: This project is ideal for intermediate students at the college level who are familiar with SolidWorks operations and can find parts in the toolbox.\nPreparation: Students should know how to operate within SolidWorks, locate parts in the toolbox, and understand what tolerances are.\nSteps!: The steps are outlined above, but first, create a sketch of the transmission system's components and determine the missing lengths. Then, identify tolerances for each length and understand the required fit (tight or loose).\nResults: The final outcome will include technician documentation detailing how to locate the necessary lengths and parts, as well as all the information needed to manufacture this transmission system in a production setting.

With this file you will be able to print Gearbox with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gearbox.