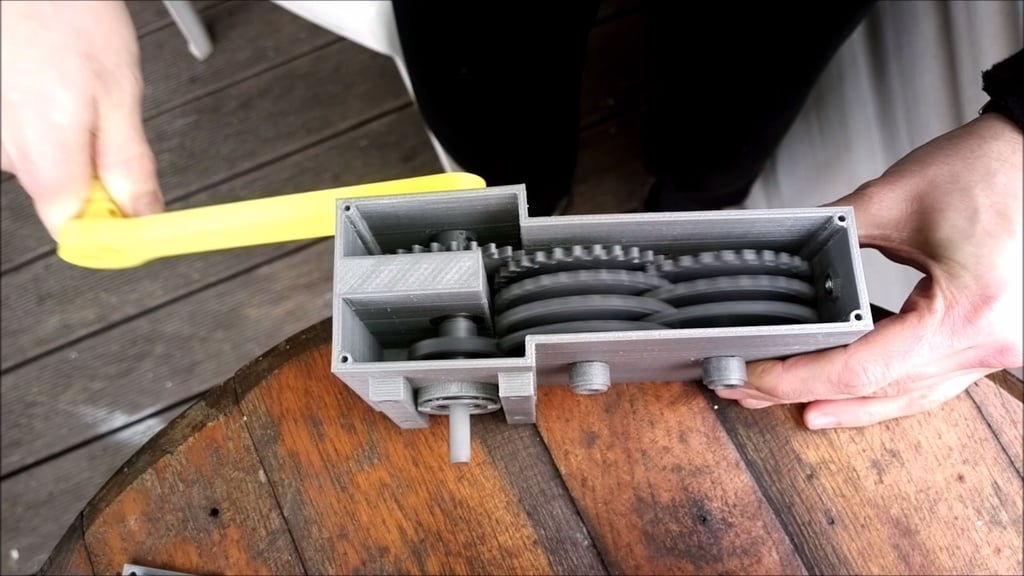

Gearbox 256 / Getriebe 256

thingiverse

Based on the provided text, here is a summary of the project's requirements and recommendations for printing: 1. **Calibration:** The 3D printer should be properly calibrated to produce clean external surfaces. 2. **Alignment:** Aligning the starting points of outer perimeters can help remove plastic bumps in a single cut. 3. **Shaft Construction:** Shafts are constructed without play, so STL files may need to be downsized in the radial direction if they do not fit together properly. 4. **Clamping Function:** Some parts include a clamping function with nuts and grub screws. However, variation of part dimensions can make it easier to implement this feature. 5. **Assembly and Lubrication:** The gearbox may need some running time before the gears work smoothly. Lubrication is helpful during assembly. Additionally, the project provides print parameters for a Velleman K8200 printer: 1. **Material:** PLA 2. **Extruder Temperature:** 190°C 3. **Bed/Bett Temperature:** 50°C 4. **Layer Height:** 0.25mm 5. **Perimeters/Umrissbahnen:** 2-4 6. **Solid Top Bottom Layer/Volle Boden- und Dachschichten:** 2 7. **Infill/Fülldichte:** 40% 8. **No Support Needed/keine Stützkonstruktion nötig** The project also includes a link to a YouTube video, likely showcasing the assembly and operation of the gearbox.

With this file you will be able to print Gearbox 256 / Getriebe 256 with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gearbox 256 / Getriebe 256.