Gear Warehouse - parametric, involute gears of all types

thingiverse

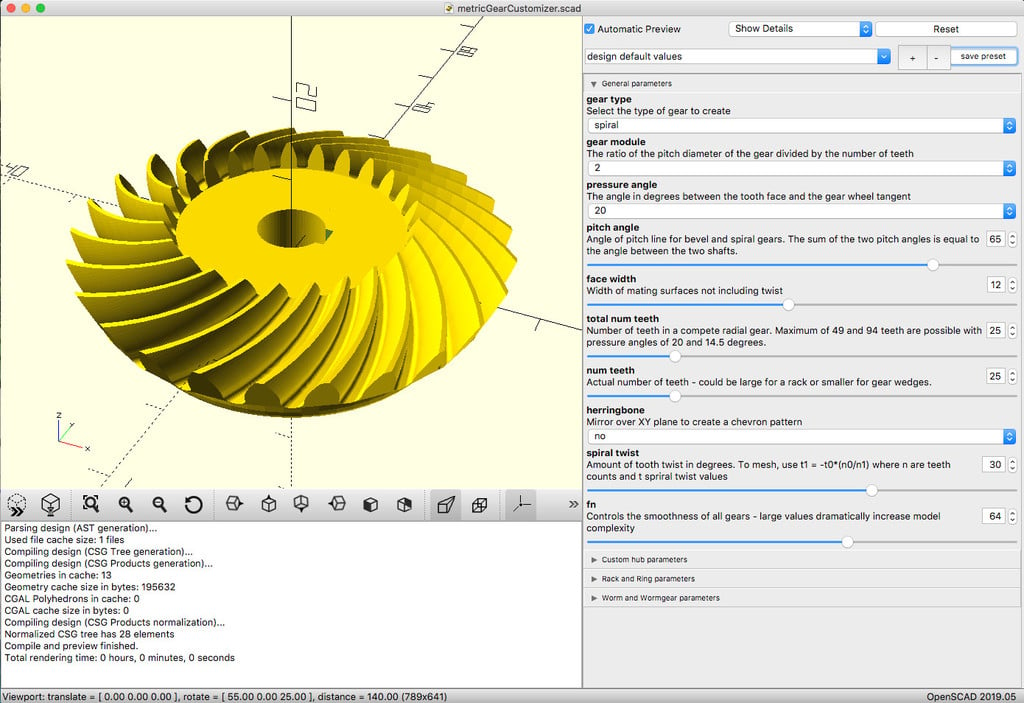

Gear Warehouse ============== The gearWarehouse can be used to create a wide variety of involute gears, either standard ISO (metric), imperial or fully custom. Involute gears have the property of continually meshing at a specific angle (the pressure angle) thus avoiding the stutter of non-involute gears as the teeth lose contact with each other. Imagine a telescope mount: involute gears would allow the telescope to smoothly follow a star as it moves across the night sky, while non-involute gears would introduce a shake that would blur the image of a long exposure. All common types of gears are supported as follows: - bevel: cone as its pitch surface - helical: cylindrical gears with winding tooth lines - miter: bevel gears with a speed ratio of 1 - rack: linear arrangement of teeth - ring: an internal gear - screw: helical gear with 45 twist angle - spiral: bevel gears with curved tooth lines - spur: simple, with cylindrical pitch surfaces - worm: a single tooth spooled around the gear core - wormgear: a helical gear that interfaces with the worm Gears are art pieces unless they mesh with each other. To ensure two gears can mesh, follow these guidelines: - Meshing gears need the same tooth shape and size, so use a common module (for metric gears) or diametral pitch value (for imperial gears). For fully custom gears, the base, pitch and outer radii will all need to be calculated appropriately. - For gears that do not spin in the same plane (i.e. bevel or spiral gears) the pitch angle parameter is used to describe the cone that the face of the teeth follow. The sum of the two pitch angles equals the angle of the two shafts. For example, a miter gear has a pitch angle of 45 degrees so two of them spin 90 degrees from each other (45 + 45 = 90). Two bevel gears at 25 and 65 degrees (25 + 65 = 90) also spin at 90 degrees. There is no need for the sum of the pitch angles to be 90 degrees, this is just the most common use case. - Spiral gears are bevel gears with a twist. When meshing two twisted gears the twists must be complimentary - as follows: the twist of the second gear is equal to the twist of the first multiplied by negated ratio of the two gears, or: `t1 = -t0*(n0/n1)` where `n` are teeth counts and `t` spiral twist values. Note this rule applies to helical and screw gears which are simplified versions of spiral gears. Wormgears also have a fixed twist which need not be directly specified. - When positioning two gears to mesh, they need to be separated by the sum of their pitch radii. For ISO metric gears this is very easy to do - simply multiply the gear module by the sum of the tooth count and divide by two (in mm), or: `separation = module*(n0 + n1)/2 [mm]` Gears with a non-zero pitch angle are created with a vertical displacement preset for simple meshing. For example, when positioning two miter gears, rotate the second one by 90 degrees and displace it both horizontally and vertically by the module multiplied by half its tooth count, or: `translate([0,gearModule*n/2,gearModule*n/2]) rotate([90,0,0])` The parameters of the involuteGear module are designed to allow gear creation with only a minimal number of parameters. Parameters that aren't provided are given appropriate defaults when possible. When input parameters don't allow for the creation of a valid gear, execution is stopped and an error message is returned. All gears are created as efficiently as possible with unions of OpenSCAD polyhedrons (and possibly an extrusion). All gears appear in 'preview' mode near instantly however 'render' mode may require several minutes depending on the complexity of the gear and the fn parameter (tens of thousands of facets for the complex gears are common). Metric and Imperial Gear Customizer =================================== Included with the Gear Warehouse are two graphical input files: imperialGearCustomizer.scad and metricGearCustomizer.scad, which enable creation of custom gears with a GUI (i.e. no programming). To use them, install [OpenSCAD](https://www.openscad.org/), and double click on one of the customizer scad files. Within OpenSCAD, go to the View menu item and uncheck 'Hide Customizer' which will bring up the user interface (click on 'Hide editor' to give yourself more useable screen space if you'd like). Click on the 'Preview' button (with the >> symbol) or press F5 to see the default gear. Now you can edit the parameters of the gear by selecting menu items from the customizer view. Note that not all combinations are valid - these errors will result in error messages in the console window to help you come up with a valid design. Once you're happy with the gear, the customizer allows the parameters of the gear to be saved so you can come back to it later. Before using 'File->Export' to save the file for 3D printing, you need to click on Render (the hourglass symbol or F6) which may take some time. If you find any errors or have suggestions for new features, please leave a comment.

With this file you will be able to print Gear Warehouse - parametric, involute gears of all types with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gear Warehouse - parametric, involute gears of all types.