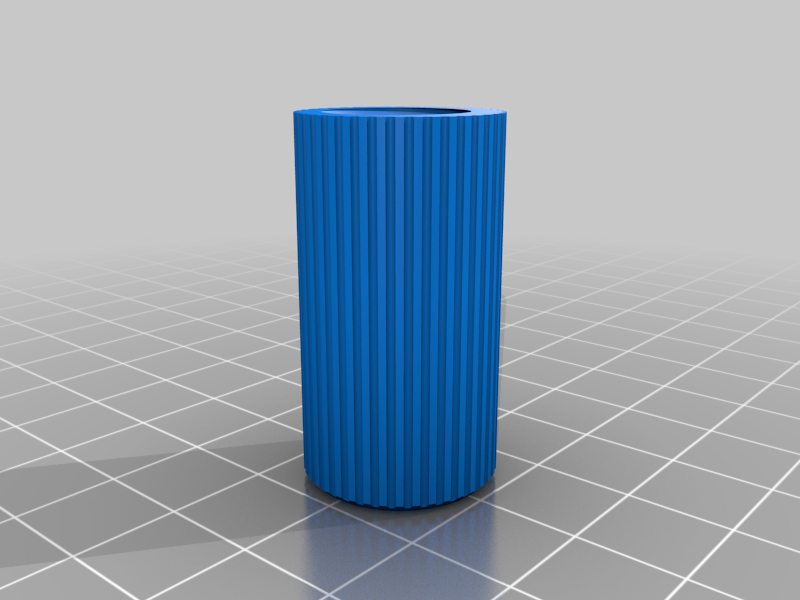

Gardena Pressure Sprayer Part

thingiverse

I printed it with PLA during testing, and it performed flawlessly. Nonetheless, stronger materials like PETG or ABS would undoubtedly enhance its overall quality. A vital step involves removing the barb from one end of the hose to facilitate easy insertion of the replacement component. To remove the barb, I carefully cut the hose just behind it, taking note of how deeply the barb is seated within the hose prior to cutting. Subsequently, I made a vertical incision in the piece that was removed, and then pushed the barb back into place by applying a small amount of heat. Please exercise caution when using chemicals with this sprayer, as their interaction with different filaments may be unpredictable. In my case, I used a water-based cleaning solution without any issues.

With this file you will be able to print Gardena Pressure Sprayer Part with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Gardena Pressure Sprayer Part.