Galileo Pendulum clock Mk I

thingiverse

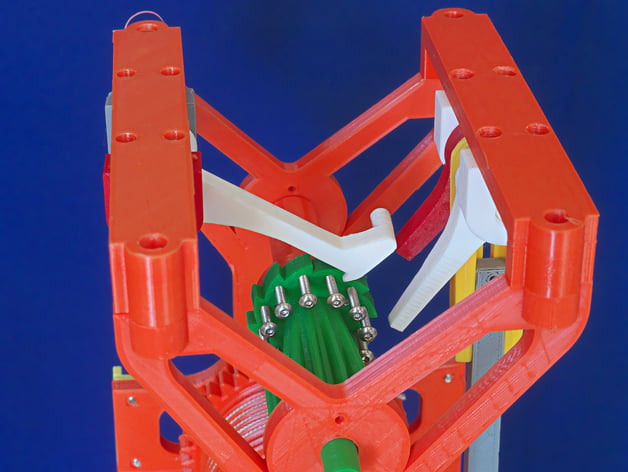

Something ignited my curiosity in the Galileo Pendulum Clock and I began exploring online, discovering some photos that inspired me to take on the challenge of designing and creating a 3D printed version. This project was not an easy feat to accomplish because many of its components had to be printed flat or nearly so. Additionally, assembling it required a significant amount of care as all the moving parts needed to move freely - without excessive play. I've uploaded the photos that served as my reference points. Designed in Moi (Moment of Inspiration), simulated in SimLab Composer Mechanical, and crafted from PLA, this project was primarily printed on an original Ultimaker. A simulation of the escapement mechanism can be viewed here: https://youtu.be/S2S6WjdXjyc And a video showcasing the finished product in action is available here: https://youtu.be/M2qSRCdEmJI Print Settings Printer Brand: Ultimaker Printer: Ultimaker Original Rafts: No Supports: No Resolution: 0.2mm Infill: 20%-40% Notes: Material used - PLA for all parts. I believe that the softer ABS would be less than satisfactory for most of the rotating components, which require smooth rotation. The exception is the pawl, which should not be too 'bouncy'. I created the pawl using PLA but opted for a softer grade - Polymaker's PolyMax. Please note that I switched to this material fairly early in the development phase and it's possible that later design changes may necessitate regular PLA for the pawl. As I've mentioned earlier, keeping the parts flat is crucial. BuildTak proved invaluable for achieving this goal, especially since my Ultimaker Original lacks a heated build plate. On the wider components, I utilized a brim. Post-Printing The design size used for shafts and holes is identical - for example, 8mm for both. I rely on shrinkage to bring the shaft slightly under 8mm and use a straight hand reamer to bring the holes very close to 8mm dead. Utilizing tapered reamers would be beneficial in opening the start of holes intended for screws. Regarding this, all screws are 3mm Button Head Caps Screws. Those in the ratchet measure 15mm long - with 12 units available. The remaining screws are all 10mm long, totaling approximately 40. You will also require lead shot (fishing weights) for the bottle weight. I used assorted sizes to maximize the weight within the bottle. The combined weight of the bottle and lead (excluding the cap) is 643gm. Initially, I employed a weight at the end of the pendulum but found it counterproductive. To address this, I had to increase the bottle size so that it could be made heavier. Please let me know if you believe an even longer bottle would be necessary. If your pendulum loses momentum, you will need either additional weight or a shorter pendulum to maintain its motion. How I Designed This I began with photos of the metal models (which I've uploaded) and worked from there. Once I had an escapement design, I ran it as a simulation in SimLab Composer Mechanical and refined the design until it would simulate successfully. I've provided a link to that simulation. To optimize the gear spacing, I made some adjustments. In the interest of making everything as 'free' as possible, the gears are 1mm farther apart than their PCDs intersect.

With this file you will be able to print Galileo Pendulum clock Mk I with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Galileo Pendulum clock Mk I.