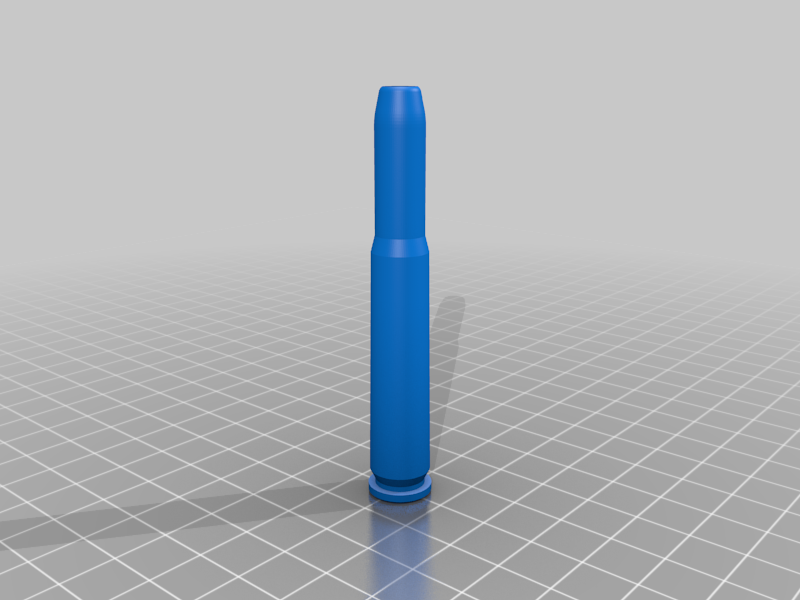

G&G Kar98K Shell

thingiverse

# READ BEFORE PRINTING! This file is designed and calibrated for printing with resin! (Tested only with Anycubic Photon Zero) **If you want to print it with an FDM 3d printer you'll need to adjust the file to your printer tolerance!** I tried to print that on 3 different fdm printers (Alfawise U30 with direct drive mod, FlyingBear Ghost 5 and TwoTrees Shappire Pro) and each one required their specific adjustments for external diameter tolerances and especially for the hole that holds the BB since it's slightly tapered. There's the Fusion360 file so you can edit that to your needs. #### *NOTE: THIS SHELL WORKS ONLY WITH KAR98K FROM G&G, IF YOU TRY TO USE IT IN A DBOYS OR DOUBLEBELL RIFLE IT WILL GET STUCK IN THE BARREL* Here are some advices to print the shell with resin or fdm: #### Printing with resin - No particular tricks needed to print this - You can print as many as you want in one shot - If you use Standard resin be gentle with the shell, if it falls from the height of your shoulder (ex: Ejecting while aiming) on hard surfaces it will probably break the neck or the rim of the shell or if you load the bullet in the chamber with too much force it will problably break the rim. - Try to use impact resisant resin like the LIQCREATE TOUGH-X (not tested by myself yet) #### Printing with FDM - If you do not have excellent adhesion to the bed print with Brim or maybe Raft - If you want to print more than one at once make sure you got a perfect retraction otherwise it'll be a pain to clean them (Stringing in the internal hole it's not relevant, just make sure it's clean where the BB will stay). - Print with strong filaments like PETG at least or it will end up like with standard resin prints. - After the print you want to sand at least from the neck up to the bb hole to smoothen the surface from the layer lines. They could cause more friction with the HopUp rubber and the extractor could slip off the rim and not extract the shell. - Another tip is that you want to put come supeglue, epoxy resin or epoxy glue on the rim to further strengthen it. (You need to be extremely precise or again the extractor will slip off) #### Advise for both printing methods I suggest to change the extractor spring with a softer one. Since this will increase the longevity of your 3d printed shells and even for the metal one's (since they're made out of pretty soft aluminium). I used 2 pen springs, since one is too soft and the extractor slip off from the shells rim, but you just have to try until you get the perfect match to extract shells and not damaging them. *P.s. If you don't know how to do that take your airsoft replica to your local airsoft shop, it's pretty easy for the extractor to jump away and lose it with the spring and the pin holding them.*

With this file you will be able to print G&G Kar98K Shell with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on G&G Kar98K Shell.