Fume Extracor For Electronics JBC Jabe integration

thingiverse

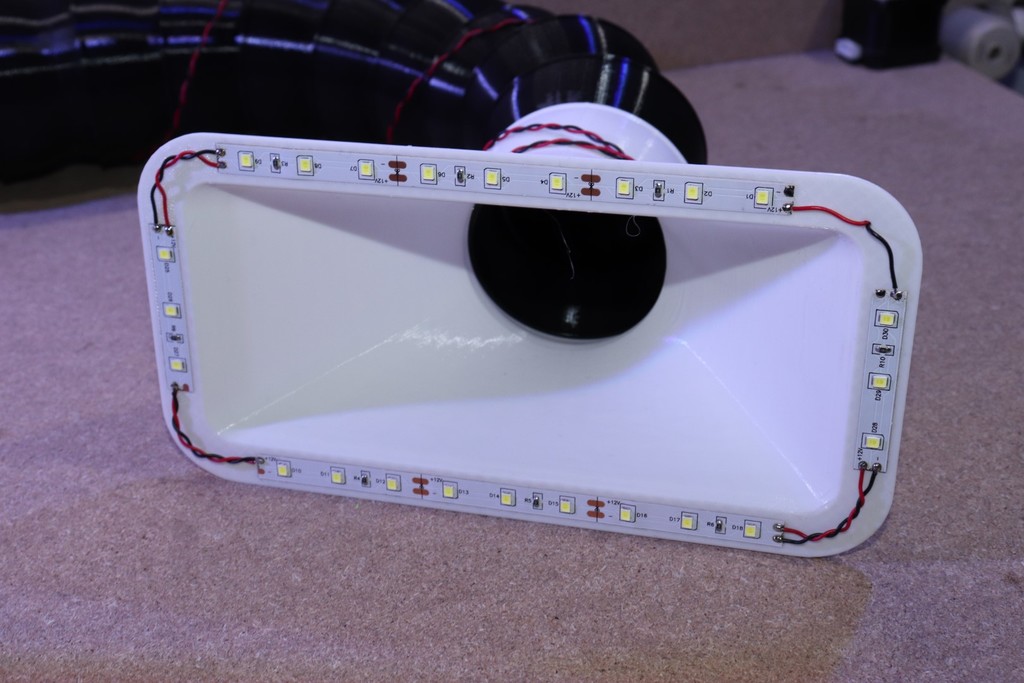

Fume Extractor for Safe Soldering A DIY Version of High-End Fume Extractors As an electronics professional with expertise in fast prototyping and a well-equipped workshop, I've created a fume extractor that rivals high-end commercial models. The correct soldering wire for reworks contains lead, and the gases from flux often include halogens, making it crucial to use a fume extractor with a carbon-activated filter to prevent these hazardous substances from damaging your health. Like High-End Fume Extractors, this design features a main unit that includes a filter, fan, and flexible hose for easy access to the working area. Some high-end models also include secondary hoses to capture fumes directly from the soldering stand, which is a fantastic feature included in my design. Each assembly can provide a primary hose and two stand hoses, with covers available if you prefer not to use the stand hoses. In commercial fume extractors, the main unit is usually placed on the floor, connected by a hose to an intermediate piece with clamps to secure it to the table. My design takes a different approach, placing the main unit on a flat vertical surface such as a wall or table back. I've created two sets of brackets to hold the main body in place and facilitate maintenance, minimizing additional filament usage. The Main Body comprises my custom line filter system, utilizing 150x150mm (Philips vacuum cleaner filters with carbon and mechanical components) and 150x160mm (kitten box filters with only carbon). Two main sizes of cartridges are available, each featuring two shapes of filtering compound and six different configurations. At this time, the two kitten filter shapes are sufficient for cleaning fumes, but I anticipate a shorter lifespan due to their limited capacity. To address this issue, I've included six additional cartridge shapes with increased longevity. The design includes files only for the Philips Large cartridge; if you're interested in other configurations, please visit: https://www.thingiverse.com/thing:4221215/files As the base for the flexible hose, I used a modified version of this design (https://www.thingiverse.com/thing:3283786), making some adjustments to enhance its performance and strength. The fan is a Delta electronics fan, rated at 24V and 90W with PWM control, sourced from industrial scrap. For optimal operation, the extractor requires at least 50W of fan power, preferably high-pressure fans. Currently, I'm running the fan at 50% capacity, which provides sufficient suction to capture all fumes in front of the tube, although it produces a loud noise. Notably, my DIY fume extractor outperforms commercial models I've used due to its thicker filter and lower airflow requirements, albeit with shorter lifetimes. The connection box on the bracket receives 24V from a PSU and distributes power to the main fan, LED funnel, and Arduino located on the soldering tray. A step-down module provides 5V to the Arduino, while also connecting the PWM input of the fan to one of the Arduino's PWM outputs. Connectors used are Molex MiniFitJR and SL (701070xx) families. The design primarily taps into M3 and M4 threads directly on plastic. To perform filter maintenance, remove one of the covers holding the cartridge by unscrewing eight screws. Additionally, I've started designing and testing a 120mm exhaust noise suppressor specifically for use with my soldering station. This design features an easy way to control speed and triggering for optimal performance; more information can be found here: https://www.thingiverse.com/thing:4593974 The funnel includes a LED mounting feature, a unique addition I've incorporated to prevent fume extractor hoses from blocking light on the workbench.

With this file you will be able to print Fume Extracor For Electronics JBC Jabe integration with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Fume Extracor For Electronics JBC Jabe integration.