Fume Chamber (Negative-Pressure, Activated Carbon Filtering)

thingiverse

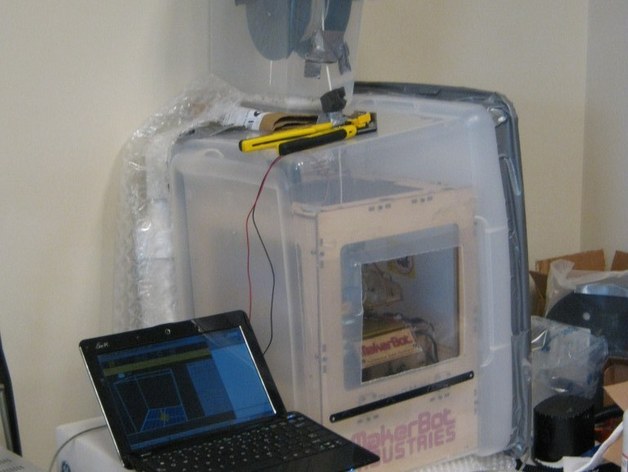

To combat ABS fumes when ventilation is unavailable, construct a Negative-Pressure Activated-Carbon Fume Chamber for about $35 and 4 Watts. This method involves encasing the 3D printer in an airtight plastic storage container with necessary access points for power, USB wire to computer, SD card slot, reset button, filament wires, filament, or buttons/card slot. Seal gaps using duct tape for optimal airtightness. Create a negative pressure inside the chamber by attaching an activated carbon filter to a computer case fan, drawing air out of the printer through the filter. A larger diameter segment containing the activated carbon reduces air resistance and increases scrubbing time. Use a fine mesh sheet, such as a cut-open activated carbon aquarium pouch, as a filter, held in place between 3" PVC tubing and the edge of a 3" PVC elbow. Activated carbon can be found at pet stores or aquariums; larger granules may require deeper beds for effective fume-filtering. The Vantech Tornado fan provides sufficient pressure but is loud, so use foam packing inserts to dampen sound. Power the fan from a 12V supply, such as the printer's own power supply. A transparent report cover serves as an access flap for easy part retrieval and ABP ejection without ABS smell. The activated carbon has lasted over 4lb of ABS in 3 months, making this method effective and cost-efficient for ABS fume control.

With this file you will be able to print Fume Chamber (Negative-Pressure, Activated Carbon Filtering) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Fume Chamber (Negative-Pressure, Activated Carbon Filtering).