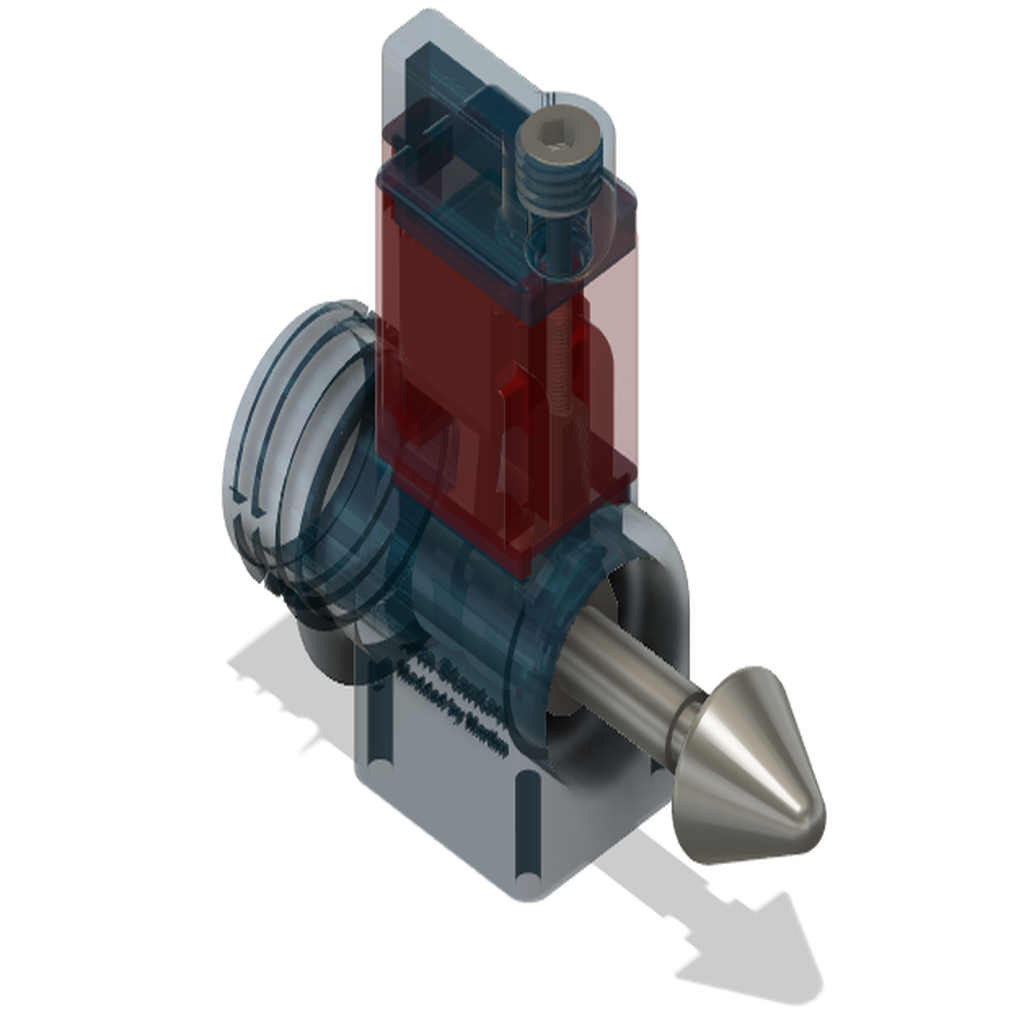

Fully 3D Printed Air Engine

thingiverse

I made the decision to modify Tom Stanton's air engine and make it fully 3D printable, eliminating the need for screws, bearings, etc. Here are the results. I reached 70PSI, but I cannot guarantee that it will work with you. You can download the Fusion 360 file, which is called air-engine.f3d, and edit it if you want to. Watch this YouTube video: https://www.youtube.com/watch?v=3OBtR_EZo9E And also watch this other YouTube video: https://www.youtube.com/watch?v=YLPY8CY5Fm4&t=657s For now, just follow Tom Stanton's tutorial. The only major change is that the connecting rod is pressure fitted, and you use superglue to connect the cylinder head. The bearing I used is 608, but choose the one best suited for your printer. I used 608_tight. Here are the print settings: Nozzle diameter - 0.2mm Print width - 0.25mm Layer height - 0.1mm Top/Bottom layers - 6 Outer walls - 6 Infill - 50% Infill type - Rectilinear Material - PLA Print speed - 50mm/s Nozzle temperature - 220c Bed temperature - 40c *These settings are required for this print. The other settings can be changed depending on your printer/filament. Here is the hardware you will need: 1pc Plastic bottle cap 1pc Presta valve (for tubeless tyres) 1pc Propeller (at least 8 inch in diameter) 1pc Rubber O-ring OD 8mm Cross section 2mm Bike pump or compressor The Fusion file is attached.

With this file you will be able to print Fully 3D Printed Air Engine with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Fully 3D Printed Air Engine.