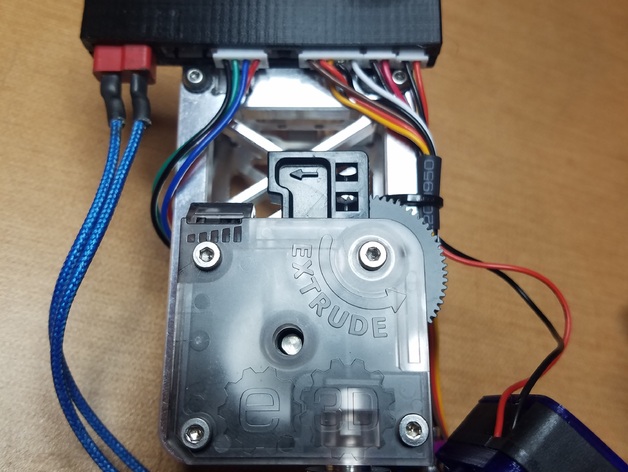

FT-5 Wiring Harness Connector and Covers

thingiverse

11/22/2016 -- Marked as a work in progress due to file errors causing bad walls and mismatched corners. The original goal was to achieve a cleaner look around the print head and wiring harness on the back of the frame. To accomplish this, I narrowed down the connections to two types: Dean's for the hotend core and JST's for everything else. This design enables quick and easy replacement or experimentation with alternate hardware without additional soldering or splicing. The plug is designed large enough to accommodate a high current Dean's connector, two fans, BLTouch, thermistor, hot end, plus one additional 4 and 2 connector headers for future add-ons or redundant wiring. I chose JST's due to their format compatibility with both JST and servo style connectors commonly found on printer gear. The design is constructed in two parts, allowing it to be used with the stock FT-5 melamine hot end carrier or the 713Maker metal hardware upgrade. After soldering wires and planning connectors, simply glue the two halves together and bolt onto the carrier. This model supports three 2 connector headers, two 4 connector headers, and one 5 connector header. The wire harness covers for the back of the printer provide a cleaner look while protecting the wires from damage or snags. I provided two upper models: one fits the stock Melamine t brackets for the frame, and the other fits the 713Maker all metal upgrade kit. Print Settings: Printer: JG Aurora A3 Rafts: Yes Supports: Yes Resolution: .1 Infill: 100% Notes: The connector was printed without rafts or support. However, while printing covers, they were either printed standing up on the large end or laying flat across the bridge, and both with rafts and supports. Post-Printing: For the connector, it was easier to place a piece of double-sided tape down onto a table after soldering wires onto headers. This held them in place for alignment before taping them together to insert into the connector housing when finished. The female Deans connector is glued into the base with either superglue or hot glue due to its identical size to the male side, making it necessary to prevent movement. The cable covers for the back require no special post-printing work. How I Designed This: I taught myself enough CAD skills using TinkerCAD to complete this project.

With this file you will be able to print FT-5 Wiring Harness Connector and Covers with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FT-5 Wiring Harness Connector and Covers.