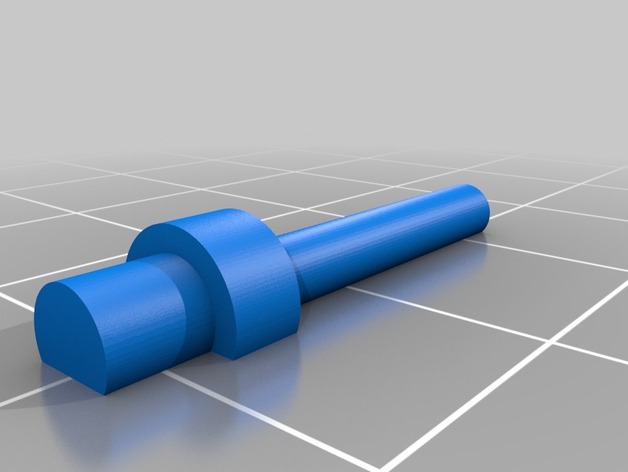

Friction Welding Rivets

thingiverse

By employing a Dremel or similar rotary tool, friction welding techniques can be utilized to perform "blind rivets" on 3D printed surfaces. As I share forthcoming projects that incorporate this method, more information will be shared about it. Upon experimentation, it was discovered that printing the rivets with long thread runs in a horizontal plane is advantageous. Printing 1/2 to 3/4 of the rivet also allows for successful spinning and fusion, similar to an entire rivet. However, printing from the base upwards tends to result in fragile rivets that break on the layer. To avoid this, it's recommended to print them flat, perhaps producing nine or twelve at a time. The provided project includes two test parts: a "base" and a "pancake" layer. By aligning the hole in the pancake with the depression in the base, you can practice the delicate touch required to fuse the blind rivet's "melt zone" equally between the rivet's base and surface of the base. After stopping the rotary tool and holding the rivet in place until it cools, applying pressure against the rotary head can help spin down the rivet more quickly. Once the mandrel is released from the rotary tool, a successful blind rivet will remain.

With this file you will be able to print Friction Welding Rivets with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Friction Welding Rivets.