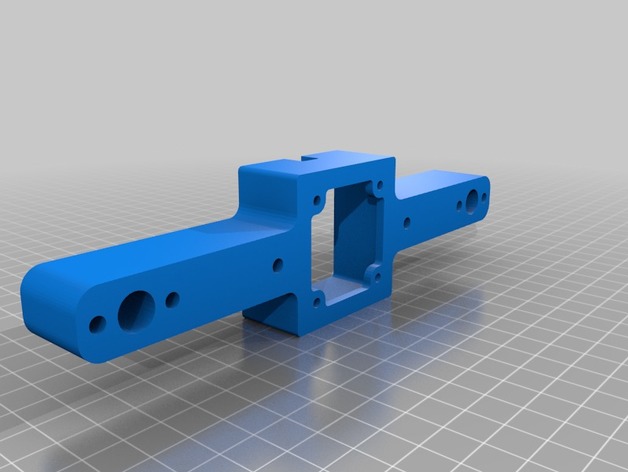

Flyingbear P902 Z axis brackets and motor mounts

thingiverse

Work in progress! Z axis bracketry for the flying bear is underway, with several versions to be designed and tested. 2/28/17 - Bottom Z axis bracket for pancake stepper and custom bearing housing: This design has not been thoroughly tested yet, but it appears that the flying bear's Z stepper motor requires little torque. Consequently, I decided to use a pancake stepper for my Titan and order another one to try on the Z axis. This new motor is 15mm shorter, allowing for an additional 15mm of Z height (don't forget to enable this in your firmware!). It has 18.5 oz-in of torque compared to the stock bear's 30 oz-in part number: 17HS08-1004S http://www.omc-stepperonline.com/nema-17-bipolar-step-motor-35v-1a-13ncm184ozin-17hs081004s-p-101.html The motor shaft will need to be shortened; you can use a Dremel for this task. Additionally, you'll require an extra stepper motor harness or cut and splice into the existing one since it's only a few inches long and un-terminated. The bracket design eliminates the stock-style bottom bracket, allowing the motor to sit directly on the extrusion, which provides another 3mm of Z height. There are two versions: FB_Z_bottom_brkt_for_pancake_and_bearing_hsng_FINAL is designed for use with a custom-made bearing flange block that I machined to hold the Z lead screw with an 8mm ID ball bearing. This version is unlikely to be used by most users; however, I'll upload a picture later. FB_Z_bottom_brkt_for_pancake_FINAL is intended for the majority of users. The motor slides into the bottom, and it's secured using four screws. The bracket then bolts in place just like the stock pieces. Print Settings: Printer: Flyingbear P902 Rafts: Doesn't Matter Supports: Doesn't Matter Resolution: 0.15-0.3 Infill: 20-40% Notes: You must print this with a bed temperature below your filament's glass transition to avoid warping. ABS requires an enclosure for acceptable results in my opinion; wrapping the bear in cardboard will suffice. Aquanet, 4mm brim, and 205/50 gave me a very nice and flat PLA print. Normally printed upside down, use supports if printed right side up.

With this file you will be able to print Flyingbear P902 Z axis brackets and motor mounts with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flyingbear P902 Z axis brackets and motor mounts.