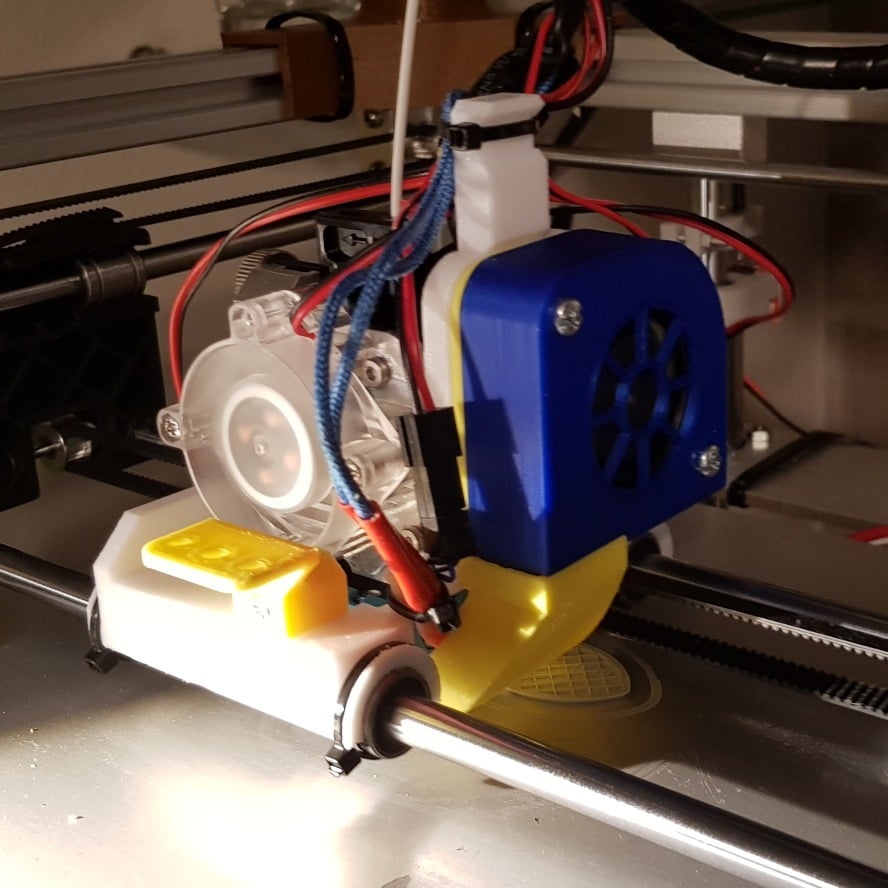

Flyingbear P902 E3D Titan Aero X Carriage

thingiverse

This is a X-carriage designed specifically for the E3D Tian Aero direct drive extruder/hotend combo, but it should work seamlessly with similar printers that have a 70mm span between the x-axis smooth rods, like the Flyingbear P902. *Note:* The belt tensioner included in this design was not created by me. You can find the original design here: https://www.thingiverse.com/thing:2018900 Features --------- * Easy mount and removal with just one screw and snap-on/snap-off functionality. * Low profile design that adds to build height. * Dual layer fan support for optimal cooling performance. * Tie wrap pegs for secure fastening. Printing recommendations ---------------------------------- I highly recommend printing the main carriage and belt clip in PETG or similar materials. PLA may become mushy if the extruder motor gets warm. The other parts can be printed in PLA, but it's up to your personal preference. Assembly ----------- To assemble this X-carriage, follow these steps: * Disassemble the stock x-assembly by removing the linear bearings. * Place the linear bearings on the smooth rods and re-assemble the x-axis assembly. * Apply a small amount of thread lock fluid to the mounting screws for added security. * Mount the motor and back plate into the carriage. * Remove the hot end and throat from the heatsink. * Gently wiggle the heatsink and guts into place, then screw it tight using thread lock. * Screw the heatsink fan into place, replacing the bottom screw with a longer one that extends through the mounting hole. * Mount the radial fan, funnel, and cover to the carriage. * Optional: add a 30mm fan to the bottom of the opposite side (under carriage) for improved airflow. See the picture for reference. * Optional (recommended): take the heatsink and fan from the stock extruder and mount it on the back of the E3D pancake stepper to keep it cool. This step is crucial, as a warming stepper can result in loss of torque. * Mount the x-carriage tensioner. * Cut the x-belt to a suitable length, leaving a little slack that can be tightened with the tensioner. * Snap the carriage into place over the linear bearings. * Secure the carriage to the bearings using tie-wraps. * Screw the belt clip to the carriage. Before you start ---- Manually check that the x, y, and z end stop lines up with the new carriage. You may need to bend the levers slightly. If you add the heatsink and fan to the back of the carriage, you'll have to move the z axis endstop to the other smooth rod due to space constraints.

With this file you will be able to print Flyingbear P902 E3D Titan Aero X Carriage with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flyingbear P902 E3D Titan Aero X Carriage.