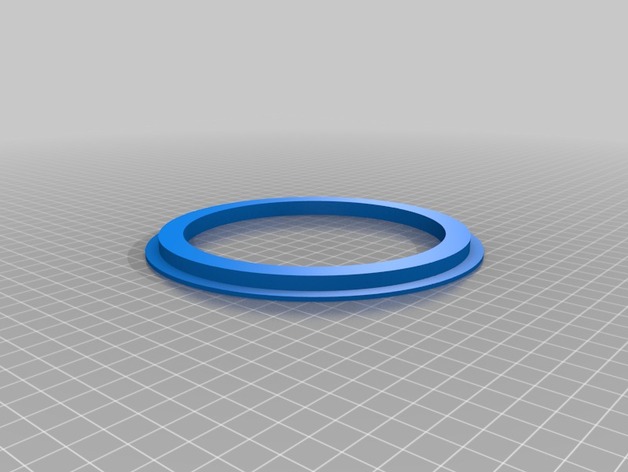

Flux 3D Printer Ball Bearing - base

thingiverse

This is a comprehensive overhaul of the MoFluxband designed by anandydy529. The problem with the MoFluxband lies in its interference with the lubricating stickers fixed underneath the filament spool, causing noise and additional friction as the balls in the ball bearing face down. The MoFluxband also increases the height of the spool assembly so that the spool potentially drags on the roof of the printer spool compartment. My new approach is to design a ball bearing base with the balls facing up against the spool, which dramatically improves friction, noise and height. This creates a spool base that allows the spool to spin freely 3 or 4 turns when loaded and spun by hand (as opposed to a quarter of a turn on the lubricating stickers). This ball bearing is designed for 1/4 inch slingshot pellets and requires some clean up after print to remove any imperfections in the print. Tolerances are pretty tight, with the balls running in a tube within the bearing. To avoid the risk of the roof of the tube collapsing, a small inner "roof" stops filament drop into the ball tube. With a little work, a single inserted ball should be able to make the complete circle of the bearing without getting stuck. Print Settings Printer: Flux 3D Delta Rafts: No Supports: No

With this file you will be able to print Flux 3D Printer Ball Bearing - base with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flux 3D Printer Ball Bearing - base.