FlexiStruder

pinshape

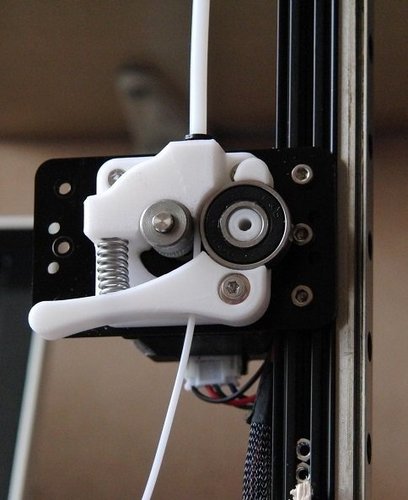

I recently encountered some issues with my EZstruder on my Kossel Pro, after hundreds of hours of printing without problems. The trouble started with occasional missed layers or sections that resulted in scrap prints - a really frustrating problem. What was happening was that the small ballbearing was slipping sideways off the filament every now and then, causing the feed to stall. I have to admit that most of my printing is done with the clear cover removed for ease of maintenance. However, even with the cover replaced, there was enough movement to allow the bearing to keep slipping off the filament. It appears the red lever arm was getting worn out and the thin section around the pivot was just too thin, allowing far too much movement. I started by wanting to modify the EZstruder bowden clamp but it was impossible to drill it out 4mm to allow the PTFE tubing to pass through without damaging the thread. I re-designed it to use the EZstruder aluminium bowden clamp fitting instead, but this still meant the end of the tube could not be placed right next to the pinch wheel and hobbed driver. However, this design is a good replacement for the standard EZstruder if you are having similar problems. This version is black in the photos. The final design I came up with uses the E3D push-in bowden clamp and is shown in white in the photos. I designed both versions as direct replacements for the EZstruder, even though I didn't need to since I have relocated my extruder to one of the uprights. In my opinion, this is one of the best mods I've made so far, along with replacing the original tube with a shorter PTFE one. The STEP files from the original design are included as TXT files - just change the .txt extension to .step and import them into your favourite 3D CAD program. A big thank you goes out to Taylor of MatterHackers for posting the original mod that inspired my design - thanks, Taylor! Important Printing Tip: When printing the white version, make sure to push the PTFE tube right through the extruder body until it protrudes where the hobbed wheel and bearing will be. Then trim off the tube to match the printed part. This enables flexible filament to be used on a bowden machine since there is nowhere for the filament to bunch up. How I Designed This: I simply added a shorter, more compact version that uses the same parts as the other version but with a different back plate. Sonny pointed out that the extruder will not fit directly onto a stepper as it needs a recess in the back to accommodate the boss on the stepper. I'll add another file for printing a spacer if you need to attach directly to the stepper.

With this file you will be able to print FlexiStruder with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FlexiStruder.