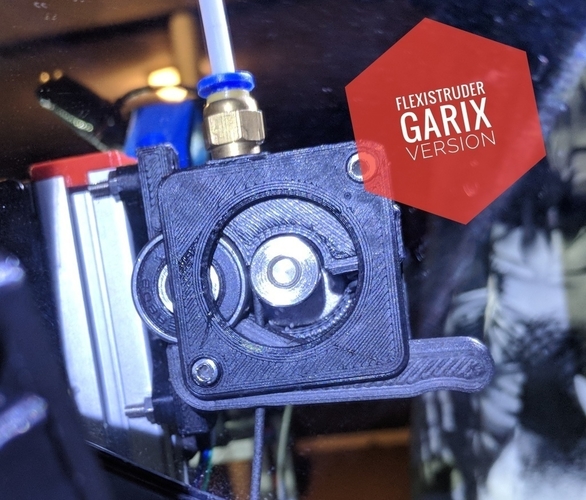

FlexiStruder - GARIX version for Mk7 drive gear

pinshape

After trying out several extruders, I keep coming back to the Flexistruder for its reliability, rapid filament changes and straightforward design. Lately, I've been experiencing underextrusion issues. Upon closer inspection, I noticed that my spring was never perfectly aligned and some pressure must have been lost due to this misalignment. Since I had ample torque on the drive gear, it would struggle to grip certain filaments and slip. To address this issue, I decided to modify the spring's alignment using a new lever. The redesigned lever ensures that the spring is properly aligned with the body of the Flexistruder while maintaining optimal tension. Additionally, I sourced locally available springs from Menards (PN#88250) which fit perfectly into my design. To further enhance the spring's tension, I modified it to compress more efficiently. I also added a cap to the design which helps keep the lever and bearing in line with the drive gear, thanks to the increased tension provided by M3x25mm screws. Both regular and reversed versions of the modified Flexistruder are included for reference. For detailed instructions on setup and other related information, please refer to the original post. Hopefully, this solution will be helpful to some users experiencing similar issues with their Flexistruders.

With this file you will be able to print FlexiStruder - GARIX version for Mk7 drive gear with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FlexiStruder - GARIX version for Mk7 drive gear.