Flexible Tube POC

thingiverse

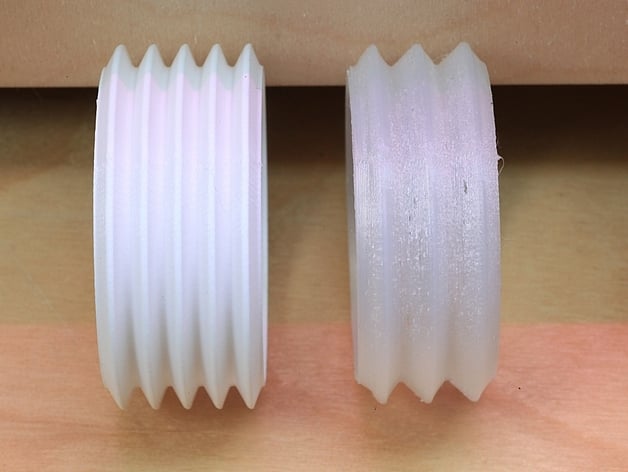

In my recent testing spree, I explored Taulman's 618 Nylon and considered trying Ultimaker's Flexible PLA. Receiving the Nylon just a few hours ago, initial impressions have been highly positive. Some images display a test print using PLA as the material, with an overhang of 65 degrees at a 20-degree slope. As I experiment with numerous new elements, I'll keep descriptions concise and provide further details in the instructions. The customizer has been put to the test, so proceed with caution when adjusting resolution parameters. Testing the Nylon revealed that 230 C provided suitable flow but insufficient layer bonding; a temperature of 254 C broke the part easily. Slowing down to 20mm/s and using a 0.15mm layer height was attempted. Future experiments include trying slower speeds with a 0.5mm nozzle and a high material-layering profile. To secure print adhesion, hairspray and glue spray were tested as alternatives to the traditional sticky tape method. A large sheet of paper served as a protective barrier to maintain printer cleanliness during testing. Previous tests with ABS and PLA yielded visually appealing parts but noted their fragility when compared to other materials.

With this file you will be able to print Flexible Tube POC with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Flexible Tube POC.