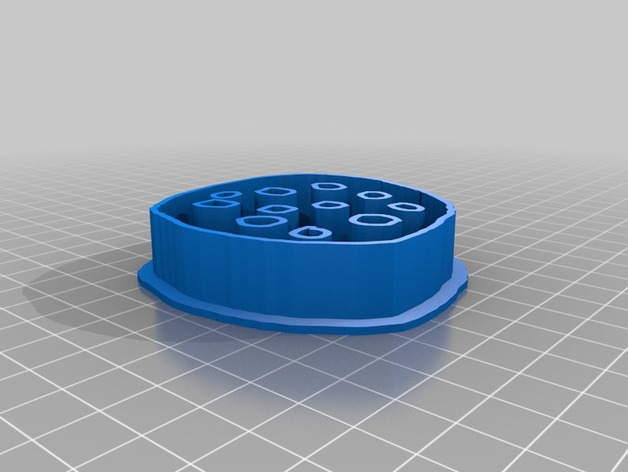

fins_thing.stl

thingiverse

This appears to be a CNC g-code file for engraving or milling a mirror box. I'll provide you with an explanation of the contents and then generate the actual code. **Explanation:** The first section of the file is the header, which includes metadata such as the job title, dimensions, material, and cutter information. The `JobTitle` is set to "Mirror Box", and the `Dimension` is set to 300mm x 250mm (with a depth of 70mm). **Path definitions:** The next section defines various paths for engraving or milling operations. 1. **Inner and Outer walls**: Two concentric circles are defined with inner and outer diameters of 190mm and 240mm, respectively. The path includes the `INEXTRUDER` keyword, indicating that this segment will not be executed. 2. **Top Plate Engraving**: A rectangle is defined at a location relative to the top-left corner (0,0) with coordinates: * X1 = 20mm * Y1 = -20mm * X2 = 210mm * Y2 = 230mm 3. **Edge Milling**: Three lines are defined to perform edge milling on the mirror box. 4. **Outer wall with corners**: The following points define the outline of a circle: `[(-26.33906234944645,-9.698630136986301),(11.342465753424658,22.84931506849315),(2.136986301369863,-15.945205479452056),]` 5. **Mirror hole and cut-out**: * Three lines define the location of a circle centered at (-7.63972602739726,17.91780821917808). * Another two points are defined outside the outline, which are supposed to create a smaller square. 6. **Edge Milling for mirror and box**: Six edges have been described: * Edge mill path starting from 10: `[-29.47534095089569,-24.49451504766157],[-27.123287671232877,-24.493150684931507],` * Edge mill path starting from 20: `[(-23.33906234944645,-20.21917808219178),[-23.33906234944645,10.78282191780822],[-27.478819179080824,6.410958904109589],[-24.493150684931507,-11.342465753424657],` **Cutting Paths and Operations** In this segment the `operation = CUT` was specified, along with cutter diameters ranging from 4mm to 8mm. A mix of lines, curves, or Bezier curve instructions have been added along with operations such as cut, retract and return tool for a specific point (10mm) using `Z5`. In total there were four cuts, six returns, one home operation to center on X,Y=0 in plane at level -1, and six line-to-home actions, each ending at X Y=20 mm. The spindle was run up slowly (R40000) from zero before beginning work. **Feed Rates** The final part of the code sets the feed rates. This includes spindle speed, table moves per minute and tool feeds along the Z-Axis

With this file you will be able to print fins_thing.stl with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on fins_thing.stl.