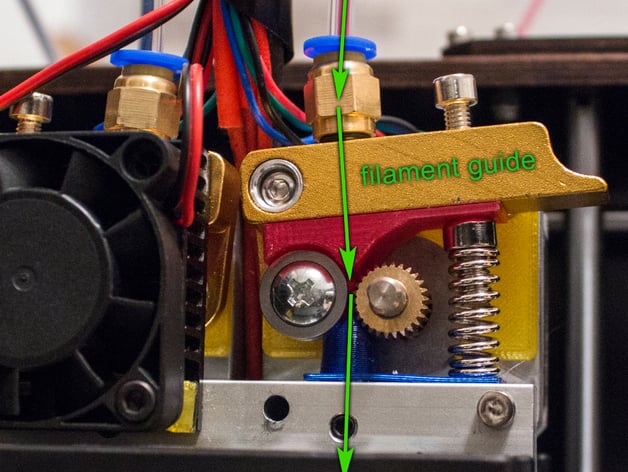

Filament guide for MK8 spring loaded aluminium arms for CTC Replicator Flashforge Dual (update: for flex)

thingiverse

It looks like you're trying to assemble and install a hotend upgrade for your 3D printer. Here are some key points from the instructions: **Printing Notes** * Use PETG, ABS, or other heat-resistant materials instead of PLA. * Adjust print settings for thin walls (0.6mm) to avoid warping or cooling issues. * Print resolution: 0.2mm * Infill: 100% **Assembly Instructions** 1. Lay down the top part on the aluminum arm. 2. Secure with ball-bearing screw, ensuring smooth rotation. 3. Add a washer between printed mounting points and roller-bearing for smooth rotation. 4. Press bottom part onto hotend metal tube. 5. Install backplate on stepper motor, securing with arm and spring-screw. 6. Install stepper motor with arm in place. 7. Adjust screw position to control filament pressure. **Troubleshooting** * If top part doesn't fit, adjust holes or try printing a new top part. * Use a drill to enlarge existing holes if necessary. * Add a flat washer between printed mounting points and roller-bearing for smooth rotation. Please let me know if you have any questions or need further clarification on any of these steps!

With this file you will be able to print Filament guide for MK8 spring loaded aluminium arms for CTC Replicator Flashforge Dual (update: for flex) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament guide for MK8 spring loaded aluminium arms for CTC Replicator Flashforge Dual (update: for flex).