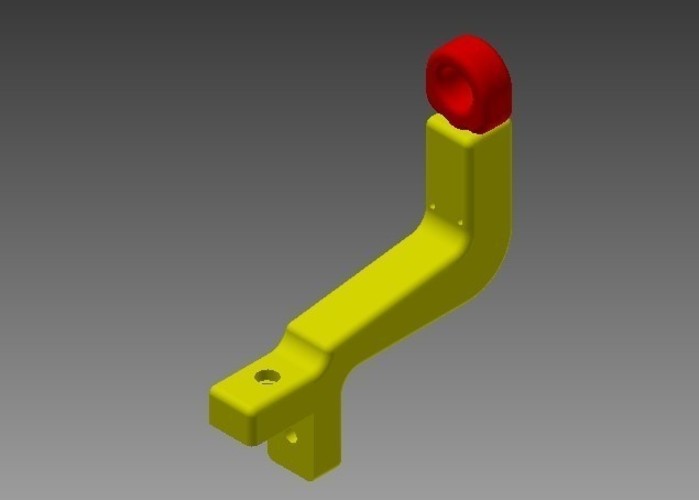

Filament Guide

pinshape

The Kossel Delta Mini 2020 requires precise filament management to achieve optimal printing results. The filament guide is an essential component that ensures smooth and consistent filament flow through the printer's hotend. To properly calibrate the filament guide, start by locating the tension adjustment screw on the hotend's side. Loosen this screw until it becomes loose enough to turn freely with your fingers. Next, feed the filament into the guide, ensuring a small amount of slack remains between the extruder and the guide. Then, gently tighten the screw while maintaining control over the filament's movement. It's crucial to strike a balance between tension and slackness within the guide. If the filament is too tight, it may bind or cause the hotend to become misaligned. On the other hand, if it's too loose, the printer may experience inconsistent extrusion rates and temperature fluctuations. Properly adjusted filament guides are vital for achieving high-quality prints with minimal defects. For optimal results, ensure that the guide remains clean and free from debris accumulation. Regularly inspect the guide for any signs of wear or damage, replacing it as needed to maintain printing performance. By following these simple steps and adhering to proper maintenance procedures, you can achieve exceptional print quality with your Kossel Delta Mini 2020.

With this file you will be able to print Filament Guide with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament Guide.