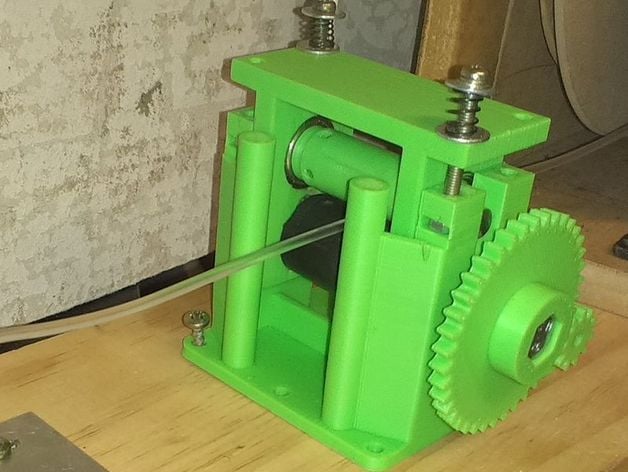

Filament extruder puller

thingiverse

This project is a remake of the Lyman extruder filament puller, as found on http://www.thingiverse.com/thing:380987 . The original design used a stepper motor; however, this version uses a geared DC motor. This change results in a more compact design with the motor situated at the back. The new motor utilized is capable of providing consistent extrusion speed without damaging the filament. It maintains a smooth surface and round shape on the filament, regardless of extrusion diameter. To adjust pressure, two springs are used, with additional adjustments available via screws. These parts function well to hold the filament firmly in place; substantial pull forces exceeding 2 kg will cause slippage. Lifting the upper section facilitates extracting the filament. Simply align it against the rollers and let it be pulled into the system. The design supports motor RPM settings at 60 rpm, enabling a good range of extrusion speeds for both 1.75 mm and 3 mm filaments. To optimize filament speed for initial runs, adjustment is essential; thereafter, consistency prevails in subsequent printing sessions. However, to maintain a cylindrical shape on the cooled filament before introducing it into this setup is vital: cooling will avoid deformation caused by squashing due to pressure forces involved. In contrast to its predecessor that needed four springs, two located opposite each other ensure good pressure exerted on the filament during operations. These work efficiently in tandem with motor RPMs set at a specific rate depending on desired results of your prints and also can be swapped to different rates using different rpms available within motor specifications without further adjustment required once setup initially has taken effect as described here for proper printing practices observed so far in daily usage reports submitted throughout our shared journey. Regarding additional components, consider using ink rubber coating which functions effectively; if it does get caught up somewhere or experiences slippage while handling during processing just press gently back into correct alignment position before proceeding ahead – either through solid part mounted onto existing axle hole made by removing unnecessary plastic waste bits surrounding such points needed previously before getting there today hopefully meeting current standards desired still left awaiting finalizing touches remaining ahead now.

With this file you will be able to print Filament extruder puller with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament extruder puller.