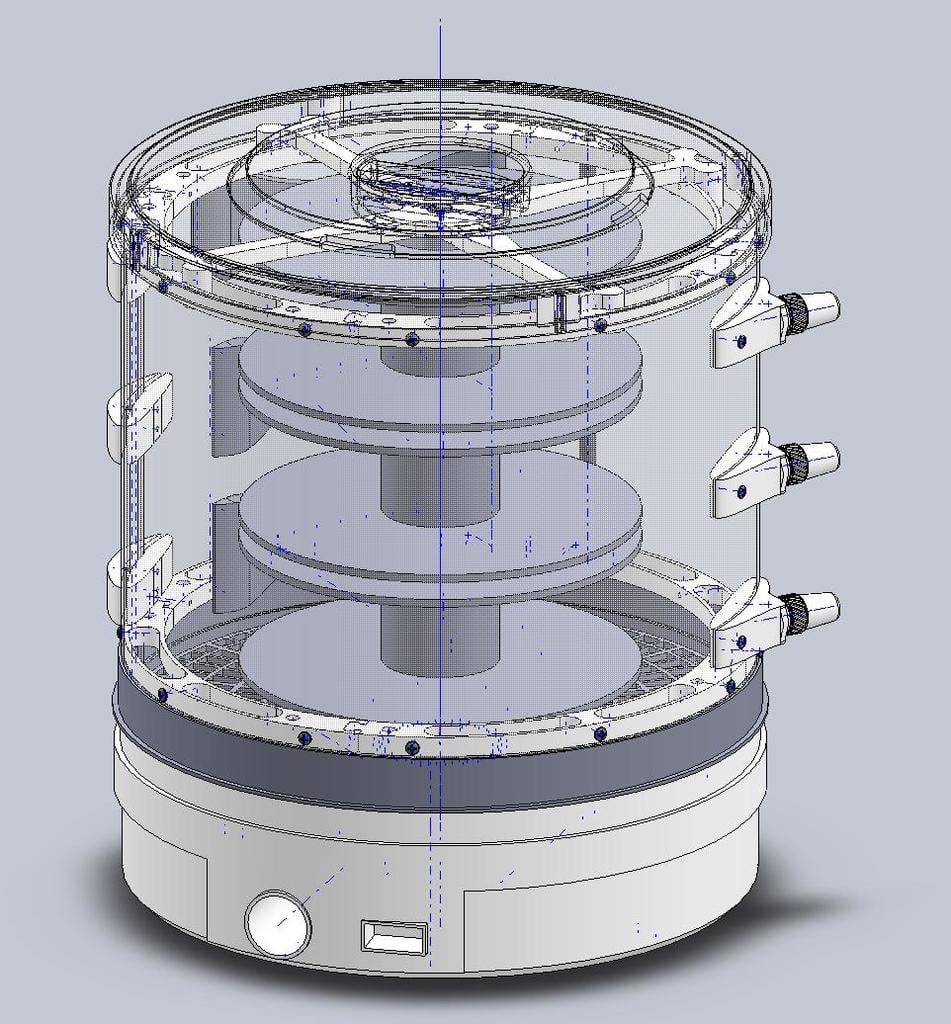

Filament dryer

thingiverse

This is a filament dryer based on the "Havsö Svamp- och Frukttork Vera 2.0" that was bought on these pages: https://cdon.se/hem-tradgard/havso-svamp-och-frukttork-vera-2-0-p41266933#fo_c=1753&fo_k=702534d35904caa8fc393843e3bd2784&fo_s=gplase https://fyndiq.se/product/10587506-havso-vera-21-svamp-frukttork/ https://www.teknikproffset.se/Hem-hushaall-traedgaard/Hushaallsapparater/Oevriga-hushaallsapparater/Havso-Vera-21-Svamp-Frukttork.htm If it is not found on these pages, you might be able to find it by searching the name of the product on your favorite search engine. This product is a filament dryer that uses a brake system to control the speed of the filament. The brake system consists of three parts: an upper, middle, and lower part. Each part has a 70mm outer width. The parts for the brake system are optional, as well as the filament filter and pass-through option. If you choose not to use these options, you can simply print the other parts without them. Here is a list of the parts that need to be printed: * 4x AxelStabalizerBar * 1x AxelStabalizerCenter * 1x Base * 3x EndClamp-Inner * 3x EndClamp-Outer * 1x FilamentBrake-70mm-Upper (70mm is for outer width of filament bobbin) * 1x FilamentBrake-70mm-Mid (70mm is for outer width of filament bobbin) * 1x FilamentBrake-70mm-Lower (70mm is for outer width of filament bobbin) * 3x Filter CAP Female 6mm tube * 4x LidSupport * 3x ThruBushing_outer (This has designed support and there is a ThruBushing_outer_WoSupport that has no support) * 3x ThruBushing-Inner * 4x Stabalizer_Type1 * 2x Stabalizer_Type2 * 2x Stabalizer_Type3 You will also need to print a shim in nylon and filament fittings for two different sizes. However, the measurements for these parts are different depending on the size of your bobbin, so you may want to make your own or provide me with the measurements and I can draw them and add them to the library. Here is a list of work that needs to be done after printing: 1: Thread the center hole in the base for the threaded rod. 2: Drill the hole in part "AxelStabalizerCenter" to fit properly 3: Thread the holes for the threaded rods for the filament brakes 4: Drill the holes in the "FilamentBrake" part to slide easily on the threaded rod 5: Cut the rod to the desired length. Take the length I stated in the list above as a guidance only. Measure what you need as I have not yet assembled the product. 6: If you used the filament passthrough option, after you mounted the parts you need to drill a hole through the PVC/Acrylic sweep through the passthrough hole. I submitted a 3D PDF so that you can look at the product better. Disclaimer 1: This product is not yet finished. I have printed all the parts but not yet assembled it or cut the PVC plastic for the sweep, but I had many requests to publish it so here it is. Disclaimer 2: The tolerances are of course suited to my environment, keep that in mind for the "press fit" parts AxelStabalizerCenter to AxelStabalizerBars I will make a statement when I am done and/or if I needed to change anything etc. The parts are available in STL and STEP AP204 file format. If asked, I may be able to provide other formats if I can find the time. Feedback is always appreciated but don't scare me as this is my first totally own published design

With this file you will be able to print Filament dryer with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Filament dryer.