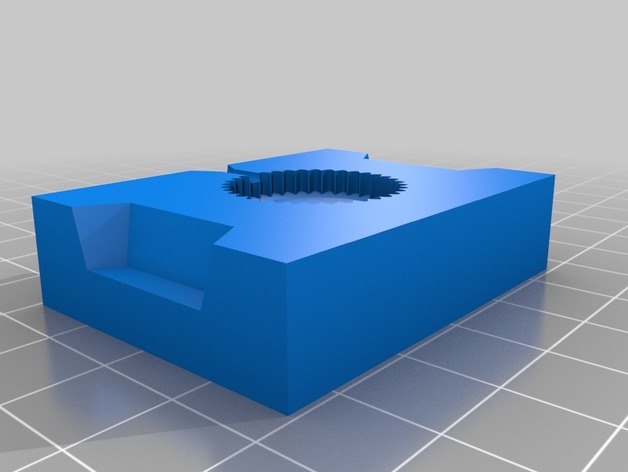

Fidget Spinner Weight Mold

thingiverse

After building a few spinners, I realized that the 22mm bearings on the spinner arms were only being used for added weight. It seemed like I could get more inertia with a heavier weight. I had some Indium casting alloy lying around, McMaster Carr PN88635K2, which has about the same density as bronze. It melts at 117F, so I use hot water to melt it and then cast parts. There are different melt points available, so if you're concerned this would be exposed to temperatures higher than 117F in the wild, choose a higher melt point. These alloys all contain some lead also, and I'm not sure about the potential health effects from the lead in the alloy. I made some casts with this metal, and it worked just fine except that Indium expands when cooled rather than contracts, making it a pain to get out of the mold. I thought about adding some draft to the sides to help this, but then I don't think it would hold as tightly in the space on the spinner. Be sure to cool the part completely before opening the mold or it will spill out. I put my cast Indium part in the mold (still clamped) into a bowl of ice water for about 15 minutes to make sure. The cast Indium parts from this mold weighed 22grams, and the bearings intended for the spinner only weighed 10g. If this is too heavy, modify the mold cavity to use less material. I'm also going to try making some parts with casting resin and iron filler next. I'm not sure how heavy these parts will be yet.

With this file you will be able to print Fidget Spinner Weight Mold with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Fidget Spinner Weight Mold.