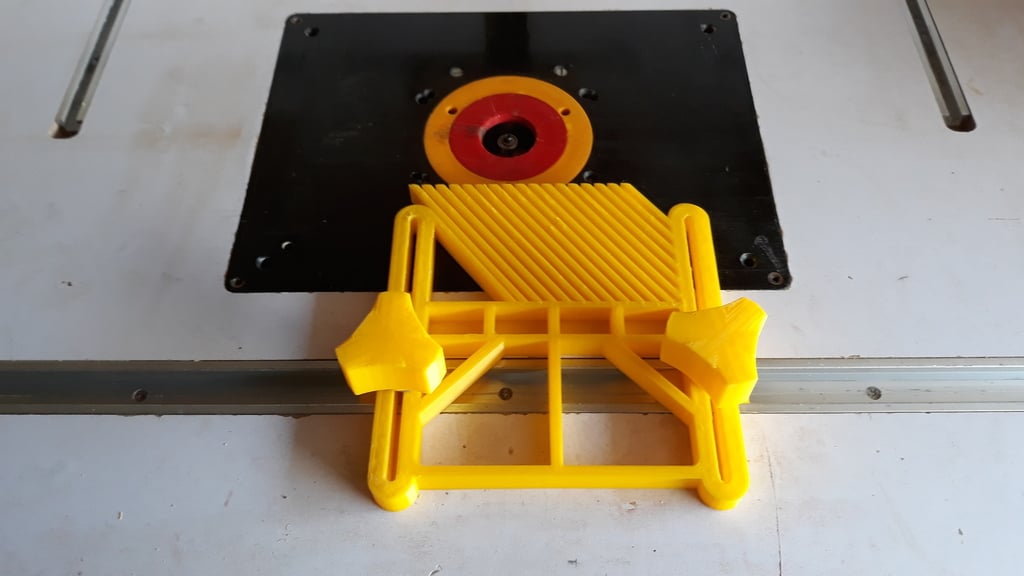

Featherboard for Router Table - With Minor Revision

thingiverse

Please note a slightly updated STL file - see below for details. Featherboard for Router ____________________ I've had a Rutlands router table for quite a few years now. https://www.rutlands.co.uk/sp+power-tools-router-tables-xact-deluxe-router-table-xact-deluxe-router-table-rutlands+rtx2000 Given it cost me less than 100 nicker back then, it's probably one of the most used tools in my workshop, after my disc sander. But the T-slot for guides and featherboards is annoyingly far from the router mounting plate, making it quite hard to source a reasonably priced featherboard that reaches close enough to the blades to be usable. But now I have a 3D printer, I simply knocked one up to my own design. Note that I've redesigned the knobs since I took the pics, because they came out far larger than I thought they would, and that was unfeasibly large, even for my big hands! The featherboard itself is a 13 hour print, but - thankfully - the clips and knobs are pretty fast. To make one, you'll need one featherboard (obviously), two knobs, and two track clips - I have 2 different types of clip: one for dome headed bolts, and the other for plain ol' countersunk. Use whichever type you need for the bolts you have handy, or design your own if the T-slots on your machine are different. You also need to two bolts, M4 by 40mm (I intended to use M5, but I didn't have any!), a couple of washers, and two M4 nuts to suit. When printing the knobs, you need to pause the print to insert the M4 captive nuts (as shown in the pictures). You then let the printer carry on printing over them. I pre-warmed my nuts on the print bed :P, to assist with adhesion of the subsequent layers. The T-slot fittings are intentionally tight. After a couple of goes at adjusting the clearance, and reprinting, I concluded it was easier to leave them tight, and manually file them to fit, rather than print them under-size and have 'em sloppy. I also found it useful to secure the bolts to the clips with a dab of cyanoacrylate, to stop them slipping when tightening the knobs. STL REVISION: ____________ I'm happy with how it works on my machine but, being a confirmed tinkerer, I felt that adding a bit more flexing room for the fingers would make it a little easier to use. So the new STL has the first and last fingers removed to do this.

With this file you will be able to print Featherboard for Router Table - With Minor Revision with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Featherboard for Router Table - With Minor Revision.