FD-626 - Filament Driver

thingiverse

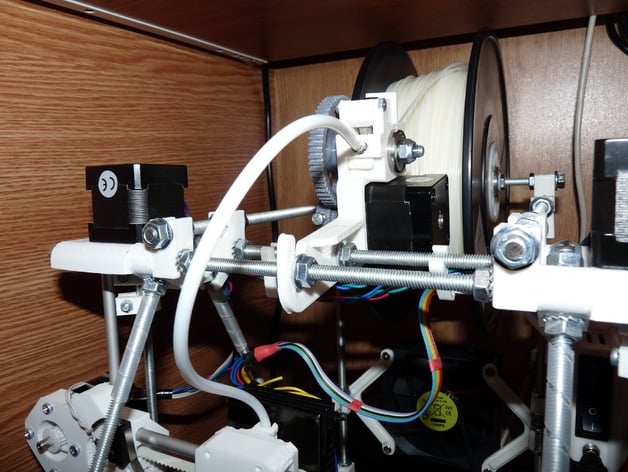

The first 3D printer kit I received was a RepRapPro Huxley, nicknamed Huxy 1. Excited by the contents, I was particularly intrigued by the "extruder driver" or as I prefer to call it, the "filament driver." A compact piece featuring tiny 623 bearings, this component was well-engineered. However, upon assembly and initial printing, a problem emerged: there was no way to attach the filament spool to the printer frame's left side where it would be if the driver were mounted on the side of the printer. To resolve this issue, I decided to place the driver on top of the printer and create a spool holder that could be attached to the frame on the backside. However, when building Huxy 2 and 3, another challenge appeared: 623 bearings were difficult to find in Romania. To address this, I compromised on compactness and switched to 626 bearings. Additionally, the M3 screw used for the driving spindle was too small for its duty, showing signs of wear at the free end of the thread due to friction with the inner ring of the bearing. This led to the creation of FD-626, revision C. The revised design retained compactness without significant size increase, featured easier-to-source 626 bearings (often cheaper), and boasted a more robust M6 driving spindle. The gear ratio remained the same as the original, with exterior teeth on the large gear for better manual rotation grip. FD-626 is directly attachable to the upper transversal rods of Huxley, although it can be easily adapted for other A-framed RepRaps. FD-626 also offers easy filament disengagement with one-hand operation. The driver features no screws to adjust pressure or hold the idler, allowing the filament to be pushed or pulled freely by pressing the tensioner. The design includes a NEMA 14 stepper motor as in the original. However, two screws must be dismantled to reach 2 of the 4 motor mounting screws. The necessary vitamins for FD-626 include M6x40 screw (driving spindle), 2 x 626 bearings (driving spindle), hobbed barrel, M6 nyloc nut, 626 bearing as pinch roller (idler), 9mm piece of M6 threaded rod (idler spindle), M3x20 screw (tensioner spindle), M3 nut, 5/6/0.5mm 7 turns spring (length ~10mm) as tensioner spring, 5/5.4/0.2mm 7 turns spring (length ~10mm) as idler spring, M3x8(10) (grub) screw, M3 nut, 4 x M3x8 screws to attach the stepper motor, and a NEMA 14 small but mighty stepper motor. All plastic parts print well with a 0.5 mm nozzle and 40% infill except for the gear, which requires 80% infill. The body should be printed with support, taking care not to cut/break the small retainers that keep the tensioner on its sliding path. If you're interested, I can create a more consistent tutorial on how to make FD-626.

With this file you will be able to print FD-626 - Filament Driver with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FD-626 - Filament Driver.