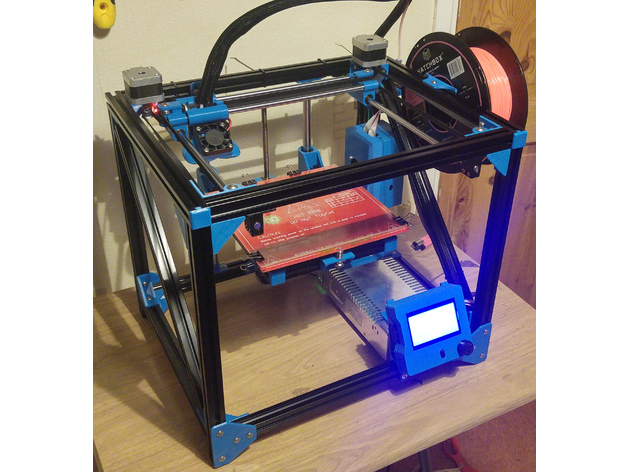

FB2020 CoreXY

thingiverse

Note - there will be no further updates to this page. Any further updates will be on the FB2020 Github page - https://github.com/AxMod3DPrint/FB2020. Originally based on the Fusebox, this printer has evolved into a unique design in its own right. Most major parts have been redesigned from scratch or thoroughly overhauled. If you want to purchase a full kit or individual printed parts, please use the contact form on https://3dprint.axmod.co.uk to place your order. The core ethos of the Fusebox was to keep part costs low, and initially this project shared the same goal. However, it is now focused on improving the FB2020 to make it virtually foolproof and highly reliable. I aim to reach a point where anyone with a set of Allen keys can easily assemble the printer. I am satisfied with the frame's rigidity, although it could be improved upon. Nevertheless, I want to maintain costs as low as possible while using printed plastic parts, which does help somewhat. I have listed upcoming changes below. All files are correctly oriented for printing. Any file marked Culain is an original design from Culain, and the only modifications made were mirroring and orienting the part correctly. Note: All bolt, rod, and hot end holes in the STLs for the Carriage and Carriers have a 0.4mm tolerance. If you require less or more tolerance, please access the SCAD files to make adjustments. There is a setting within these files to modify the tolerance. Belt Tensioning: To achieve optimal tension, loosen the motors so they are at the end of the bolts in the Y direction. Pull the belts as taut as possible manually, then tighten the motors back up to apply full tension. I am currently working on developing a more effective tensioning system. https://youtu.be/WNDfNemOfFM - Gayer-Anderson Cat printed with Whiter Generic PLA at 80mm/s and 0.1mm layer height. https://youtu.be/yOhGpVYnDCI - Aztec Chief printed with ColorFabb NGEN at 80mm/s and 0.28 layer height. https://youtu.be/bmPf83OeyGA - Printing the Rigid Coupler in ColorFabb NGEN at 80mm/s and 150mm/s travel speed, with retraction settings still being refined, which resulted in a slightly stringy print. https://youtu.be/XaOWR-UzrOI - 2nd Print of #3DBenchy Timelapse. Print Settings: Printer Brand: RepRap Printer: FB2020 CoreXY Rafts: Doesn't Matter Supports: Yes Resolution: 0.28 Infill: 50-70% Notes: Please print the parts as oriented, with support required for Extruder Carriage, Carriers, Idlers, layer fan assembly, and right side idler rod mount. All parts need to be printed at 70% infill for strength, except for Bowden tube clips (100% infill) and RAMPS mount and Z endstop mount (15-20% infill).

With this file you will be able to print FB2020 CoreXY with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FB2020 CoreXY.