Fastening Laser Cut Acrylic

thingiverse

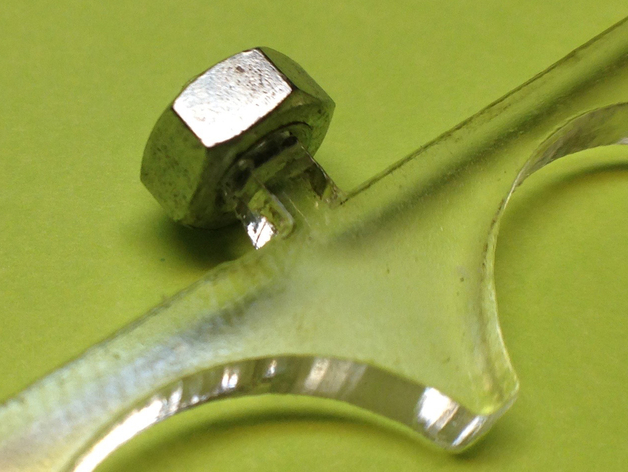

There are numerous ways to connect laser cut pieces, each boasting its own set of advantages and disadvantages. Some methods are more intricate, bulkier, or stronger than others. T-bolt joints, slotted joints, and various other techniques abound. However, I've yet to come across this specific method: threading a square cross-section length of plexiglas itself. To create an effective tab on your piece, design one with the appropriate length. The width should match the thickness of the material used (I employed 3 mm), while the length should be equivalent to the thickness of the part it will pass through plus the thickness of the nut and some extra space for safety. I also rounded off the ends slightly; this simplifies starting the threads, but it's not essential. The mating piece must have a corresponding 3 mm square hole. Using a tap & die set, thread the tab with 4 mm being an optimal choice for 3 mm material, which is my go-to thickness. The ratio should hold true for other thicknesses as well, although experimentation may be necessary to confirm this. I successfully threaded the piece by holding it and the die in my hands. Starting can be a bit tricky due to the die's expectation of a cylindrical shape with three cutting edges and the piece having four corners. To overcome this challenge, keep the piece straight, move at a slow pace, and once it begins to thread, the process becomes much easier. The attached file contains a test piece you can use to try out this method. While it may not be the most robust technique, it suited my needs for my current project, and I'm sharing it with the maker community in the hopes that others will find it useful.

With this file you will be able to print Fastening Laser Cut Acrylic with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Fastening Laser Cut Acrylic.