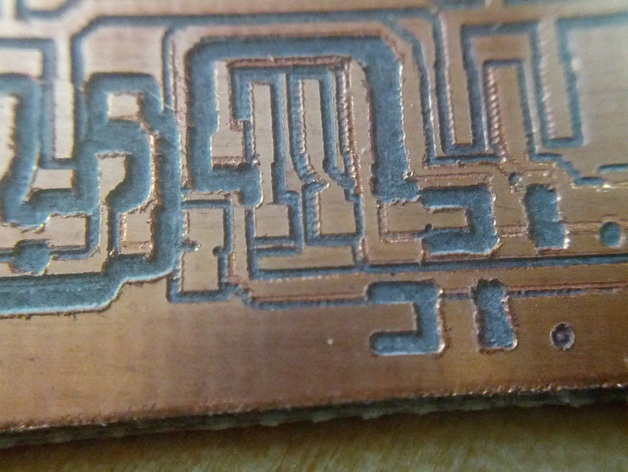

FAILED RepRap PCB Routing

thingiverse

I ended up with a functional PCB but the process was time-consuming and barely satisfactory; thus, I reverted to using Ferric Chloride. Initially, I purchased an RS 547-616 PCB Drill for my printer, connecting it to the hot end supply for control purposes. Employing Eagle 6.3.0 Light, I worked on a project called CarV2 within the last three years (last remembered in July 2013). The required code was found in ulp\pcb-gcode-3.5.2.11.zip, and the original version resided in ulp. A readme.html file within the same directory provided additional guidance. I modified the source at some point, which is saved under MyOld. Profiles\MetricPrusa.pp was also created for GCode Style customization. To secure the PCB material during milling, double-sided carpet tape was used on the bed. However, using shears to cut the material resulted in an uneven edge, causing difficulty in milling copper without damaging the fiberglass. A 30-degree engraving bit was employed for this task but wore out quickly after each PCB. The drill's weight and speed might have contributed to the slow routing process, taking a whole morning just to complete a 2" x 1" PCB. Ultimately, I abandoned the method and returned to using Ferric Chloride, as the results were unsatisfactory.

With this file you will be able to print FAILED RepRap PCB Routing with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on FAILED RepRap PCB Routing.