Face Shield Visor CR-3D remix wireframe fast print large stacks

thingiverse

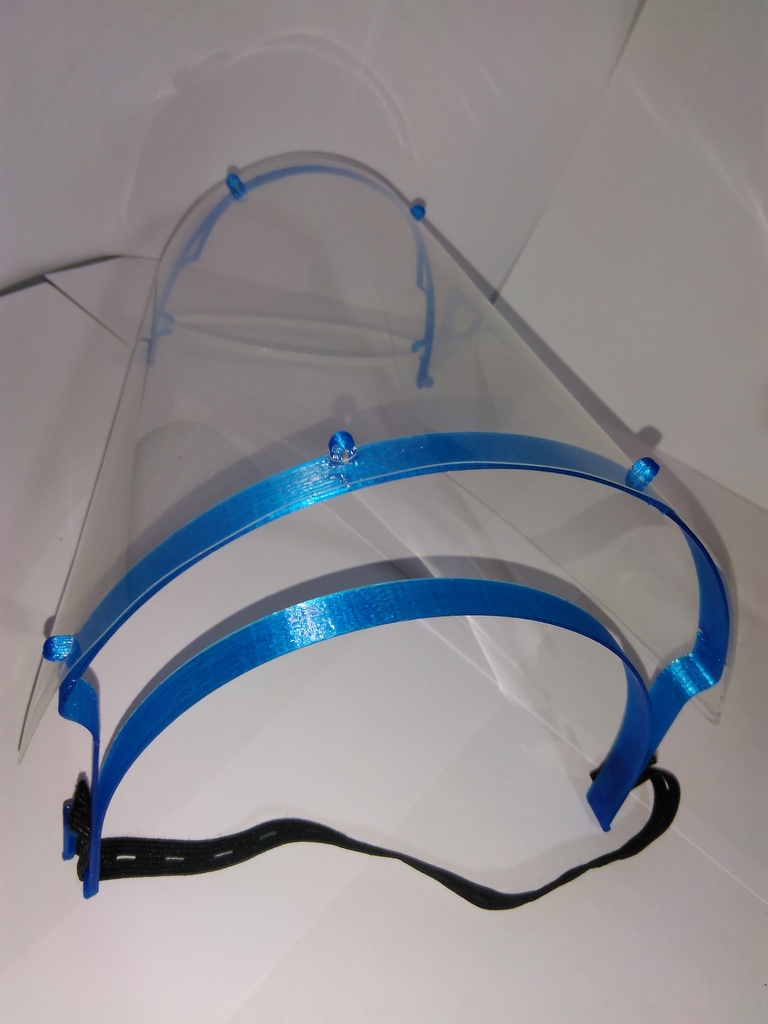

This is a fast print wire frame remix of the popular and highly optimised CR-3D C8.1 design, which has been further optimized using Manufacturing Systems Engineering design principles learned at Delphi Technologies. The result is a lower weight, easier printing, large 50x stacks on a delta printer, and lower material costs. With this design, I can produce approximately 30 parts per day while running overnight, with a 50x stack taking around 1.5 days. All of my various stack sizes STL files are included so you can select what fits your printer. The hole pattern and visor material use the original CR-3D design's 888 4-hole punch pattern, which enables very fast processing of laminates compared to Prusa hole spacing. I recommend using 250-micron laminates for stiffness, as thinner ones will still work okay with the bottom chin reinforcement. If users need fine detail vision, such as tattoo artists, I suggest using A4 0.5mm PETG sheets from Amazon or potentially overhead projector acetates as a cheaper alternative. Using washing up liquid as a cheap anti-fog solution and informing your users is also recommended. The cycle time and cost reveal that prints take approximately 30 minutes per part (excluding reinforcement) and I get around 50 face shields and reinforcement pieces to 1 kg of PETG filament. The total cost of manufacture, sterilization, elastic, zip ties, and packing is approximately £1. No infill or top or bottom layers are used; only two walls are printed with a 0.6mm nozzle. Alternatively, it can be printed with three walls and a 0.4mm nozzle. The wireframe design optimization originated from Mike's application to the Prusa RC3 design called 'RC3 Stack - High Speed Print'. I applied the same technique to the CR-3D design. This requires a solid fill model where only the walls are printed. Several changes were made to the CR-3D C8.1 design, including re-engineering the STL file and making ergonomic tweaks based on user feedback. The sides have been extended back to prevent pressing on the sides of the head. A flick/curve was added to the ends so there is a radius and does not poke into the skin. The hook geometry has also been modified with a vertical hole for tying elastic. Text has been removed, as it causes instability in the tool path when only printing two walls with high material flow. An optional bottom reinforcement featuring 2 side loops for a 300mm 4.6mm wide zip tie was added to the 888 4-hole punch pattern. The sterilization procedures must follow Prusa's guidelines when packing, acting as if you have COVID-19. Wear gloves and a face shield as a minimum, preferably with a mask. Work in sterile conditions, individually bagging parts immediately after sterilizing using Ethanol (surgical spirit) bath or other options such as alcohol, UV-c light, or weak bleach solution. Josef Prusa advises: "If you want to manufacture shields for others, PLEASE READ THIS CAREFULLY." Wear a face mask and fresh pair of gloves when collecting each batch of printed parts. Store the parts immediately in a sealable bag. Talk with whoever you're making the shields for about your manufacturing environment. There is still debate about how long the virus survives on plastic, but most sources mention 2-3 days. The licence and selling of face shields are shared under non-commercial license. It would be great if you donated these shields to those in need for free. If you need to cover your production costs, we're okay with you selling the shields for production cost. However, we do not want to see these shields on eBay or Amazon for extortionate costs. Please accredit CR-3D for the ergonomic design of this face shield, as I have only optimized it for large batch production and made minor tweaks based on feedback. Ensure your users know the design origin, as their work has surpassed the original Prusa design in my opinion and is why I made the switch.

With this file you will be able to print Face Shield Visor CR-3D remix wireframe fast print large stacks with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Face Shield Visor CR-3D remix wireframe fast print large stacks.