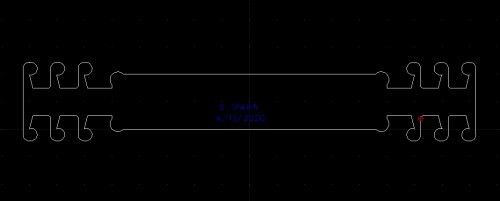

face mask ear saver ( for laser cutters )

thingiverse

Humans can now create laser cutters that are not 3D printers. A thought-provoking idea is to use materials other than 3D printer filament, such as cutting out existing recyclables. Some people have already made these laser cutters. I created one last night after looking at a model the Boy Scout in Canada made and another more recent laser-cut one. I cut several pieces last night using various materials that are often thrown away or recycled. Several materials were tested with the idea of using things that typically end up in the trash or recycle bin. Cardboard was used, but it's not very strong even when doubled up. However, if single-layer cardboard is doubled over, it could work. Plastic from milk cartons was also tried, but it's too thick. Yet, doubling its thickness could make it a viable option with real potential. Foam from meat packing was used as well, but it has no strength at all and cuts easily. Vinyl or PVC like the material found in blind shutters showed high strength, but PVC must be vented out of the shop area to avoid toxic fumes. Single-layer cardboard cut okay without burning, and when doubled up, it could be useful as a throw-away item with good flexibility. However, corrugated cardboard doesn't cut well and burns easily, making it not suitable for use. Foam from meat packing cuts great and shows excellent detail, but its downside is that it has no strength whatsoever and should be handled carefully. Dropping the foam could cause it to crack or break by its own weight. Milk carton plastic (which may contain PTFE) was also tested. While it's a bit on the thin side and doesn't cut great due to melting issues, doubling it up would give it strength. A thicker sheet of the same plastic material could be reused. A vinyl or PVC blind strip about 1mm thick has enough strength to be reusable and good flexibility. However, it may need to be run over twice to cut well. The downside is that PVC fumes are extremely toxic and must be vented out of the shop area. UPDATE: I have made some adjustments after seeing how weak the foam cutout was. The base of the tong has been thickened, and the end tongs reduced from 6 to 4, which will reduce print time and make it more suitable for use with certain beds or swivels that have a physical size restriction. Feel free to comment on any improvements you think could be made. This design is not ideal but works well enough to cut out at 10mm/s in 1:16m:s. Of course, this was achieved without using high air pressure and with reduced power; with these adjustments, the cutting time could be halved. A 2D CAD program was used to create this laser cutter design.

With this file you will be able to print face mask ear saver ( for laser cutters ) with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on face mask ear saver ( for laser cutters ).