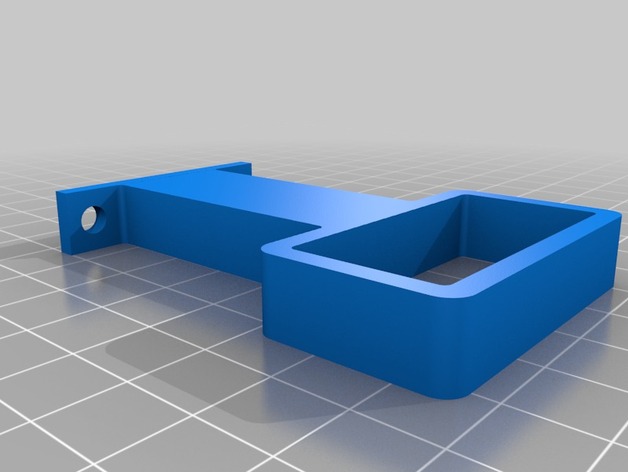

Extrusion Brace / Wall Mount Clamp

thingiverse

My C-Bot and several others I've seen are fairly tall, which causes them to shake and oscillate due to the height and speeds at which the carriage and hot end assembly move. To counter this issue and attain higher speeds and print quality, I created an OpenSCAD design that allows you to create a clamp that wraps around aluminum extrusions and secures to a wall or other stable mount point. The customizer and design accommodate a wide variety of extrusion sizes. Additionally, the ability to retro fit a printer using a multi-piece clamp or create a fully enclosed clamp for installation during printer assembly is included. If you're feeling adventurous and want a cleaner look, you can disassemble the necessary pieces to slide a single piece clamp on. Updates: 10-17-2017: A dedicated flag/switch has been added for adding a gap in the bar for LED lights. 2-8-2017: The positioning of holes for screws/bolts has been fixed. The size of holes has also been increased to better fit M5 bolts. 10-2-2016: The ability to create a gap in the clamp, useful for making room for LED light strips attached to the extrusion, has been added. Additionally, the option to create empty space in the bar by using an X pattern for support instead of a solid bar has been included. A few examples of these changes have also been added. The code is GPL and can be found in the github repository for my hot end mount generator, which is also available on thingiverse. I've included a couple of sample STL files, including one for a 20x40 extrusion clamp that's 50mm long - you're in luck if you need something like this! WARNING: For proper part strength and operation, this must be printed on its side as shown and produced by the STL files. Printing it vertically can almost guarantee layer separation if you mount it to the printer and get things moving. Suggested usage: Print two clamps for every side to be secured. Secure them on every side of the printer if possible. You want the force of the printer to be absorbed by pushing forces, not pulling ones if possible. Mount the clamps on the extrusion as far out to the edges of the printer as possible - wider is better. Don't try to use a single clamp in the middle or one edge; that will either bend the extrusion or create torsional forces in the frame. My advice is to use two clamps per side at the edges or no clamps for a side that only allows for one. Better to evenly oscillate than twist the frame. Hot End Mount Generator: http://www.thingiverse.com/thing:1141659 GitHub Repository for both: https://github.com/croadfeldt/Roadfeldt_3d_hczf_mount

With this file you will be able to print Extrusion Brace / Wall Mount Clamp with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Extrusion Brace / Wall Mount Clamp.