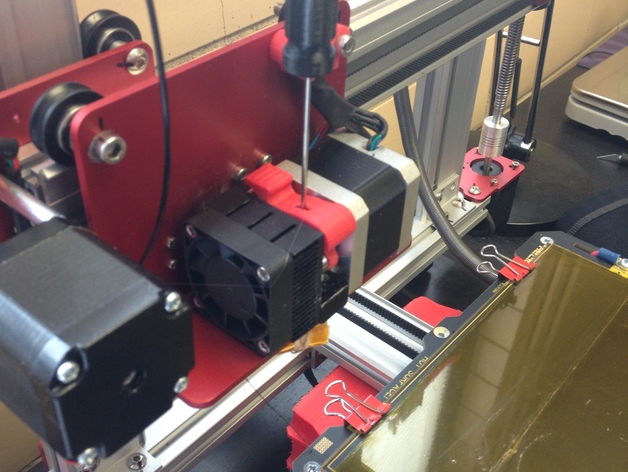

Extruder Cleaning / Alignment Tool

thingiverse

This gadget helps dislodge a 1.75mm extruder that's stuck. It pushes material through a sizzling extruder and also enables the extruder to align correctly during assembly. The metal rod is made from a standard 2mm bike spoke, which is commonly found at most bike shops. **Assembly Instructions** Firstly, print the part with an infill of about 80%. Next, pay a visit to your local bike shop and ask them for a retired bicycle spoke, as they come in various sizes, including 1.7 mm and 2mm. A 2mm spoke worked perfectly fine for me. Now, take a hacksaw and cut the spoke into two halves – never use wire cutters as it will distort the spoke. File the ends to ensure they are flat and free of any rough edges. Apply some glue to secure the spoke into its handle, and you're all set. This handy tool serves several purposes: first, it helps remove stuck or jammed filament lodged in the extruder by functioning like a plunger; secondly, it aligns the extruder so that it's perfectly in line – you should be able to gently poke the metal rod through the extruder until it reaches the hot end. If there's resistance, use the rod to locate the trouble spot and clear the path. Ideally, there should be a smooth and unobstructed pathway from the top of the extruder to the hot end if everything is properly aligned. **Important Notes** Please remember: 1) Most bike shops will happily give away old spokes at no charge; do express gratitude to them and explain how you intend to use these bike parts – it's not only good for our community but also polite! 2) If the hot end is activated, the metal rod can get quite hot, so handle it with care to avoid any accidental burns or melting mishaps.

With this file you will be able to print Extruder Cleaning / Alignment Tool with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Extruder Cleaning / Alignment Tool.