Extruder Calibration Aid

thingiverse

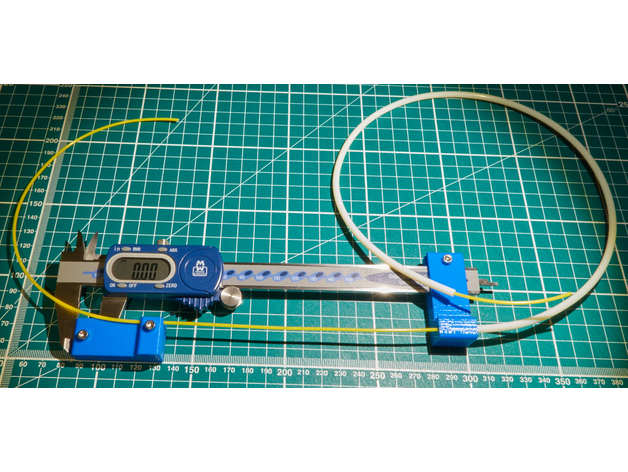

You have two parts that clamp to digital callipers, enabling precise measurement of filament drawn into the extruder during calibration. One part clamps to the end of the calliper with a PTFE tube inserted into it. The other end of the tube goes to the extruder. It doesn't matter if the extruder has no fitting for the tube; as long as the end of the tube butts up against the hole in filament clamp, and the filament can be drawn freely through the tube. The other part clamps to the moving jaw of the calliper with a clamp for the filament coming from the filament roll. To use it, just slacken off the filament clamp screw, close the jaws on the calliper, tighten the filament clamp screw and zero the caliper. Then run 100mm of filament through the extruder as per a normal extruder calibration. The calliper gives you a direct reading of how much filament was actually drawn into the extruder. In early stages of calibration, it may be best to only run 50mm of filament since the calipers will have a max travel of about 105mm with parts clamped to them. Print Settings Printer Brand: Wanhao Printer: Wanhao Duplicator i3 V2 Rafts: No Supports: No Resolution: 0.4mm nozzle, 0.2mm layer height Infill: 20% Notes: Printed with PLA

With this file you will be able to print Extruder Calibration Aid with your 3D printer. Click on the button and save the file on your computer to work, edit or customize your design. You can also find more 3D designs for printers on Extruder Calibration Aid.